STC Ratings for Walls

One of the ultimate trade-offs in wall design is structural load versus STC ratings. It’s a relatively straight-forward proposition to achieve an STC 50 on a 25-gauge stud wall, but if the wall requires shear strength or structural load capacity, then the gauge size and spacing become a major hindrance.

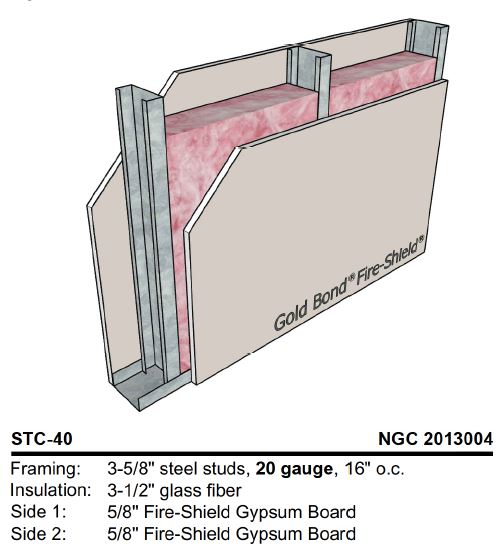

For instance, a 25-gauge 3-5/8″ stud wall at 16″ on center achieves an STC of 44 (all ratings assume fiberglass batt). However, the same way wall with 20-gauge studs hits only an STC 40 – see figure below. The standard rule of thumb is that you will lose 3-4 STC points by moving from 25-gauge to 20-gauge studs, and likewise, 3-4 STC points by moving from 24″ on center to 16″ on center. Therefore, the same UL assembly can fluctuate by 6-10 points just by changing the stud gauge and spacing.

This is a remarkable fact that is forgotten on many specifications and wall schedules. As the wall becomes stiffer it loses flexibility, which is critical in dampening inbound sound energy. Reducing stud spacing and increasing stud thickness (lower gauge) may make the wall stronger, but it also allows the wall to transmit more sound.

Steps to Achieve an STC Rating on Load Bearing Walls

- Do all walls need to be load-bearing? Often-times only the corridor walls or demising walls need to bear load, but architects will keep just one stud design in the wall schedule for all partitions. Make sure that only load-bearing walls are designed for 16- or 20-gauge studs. This will save a significant amount on stud costs, as well as minimize the additional layers needed to achieve an STC 50.

- Decide what Target STC you need to hit. While you need an STC 50 for multi-family, you may only need a 40 for many office spaces, and as high as STC 55-60 for hotels, and even STC 65+ for movie theaters and other special classifications. (NOTE: Click here for an aside on Movie Theater Soundproofing).

- Determine the most cost-effective way to hit the STC needed. Use our STC Calculator for the STC ratings of your wall design, or contact one of our STC engineers to provide a lab-tested assembly for your wall.

- HINT: If you’re stacking drywall layers to achieve an STC rating, you are not doing it in a cost-effective way.

- On thicker gauge studs, ensure that Resilient Channels are NOT used on walls with cabinets, shelving, TVs, or other mounted units. Instead, consider staggering the studs or using a double-stud wall. If this cannot be done, consider resilient clips and hat channel that are much more effective at achieving field STC ratings than their resilient channel counterparts.

Remember that there are many ways to achieve an STC 50, or STC 60 and 70 for that matter. It is largely dependent on the spacing needed for the wall, shear and load-bearing restraints, and ultimately, cost! For instance, one STC acoustic lab test recently commissioned and completed by Commercial Acoustics, achieved an STC 52 on 20-gauge EQ studs, and one layer of drywall on each side with a single layer of Wall Blokker Lite. If an STC of 50+ is needed for the load-bearing wall, this would represent a significant cost and schedule savings over traditional construction techniques.

Summary: Soundproofing Membranes may be a cost-effective alternative to multiple drywall layers if STC 50-55 is needed on Load Bearing Walls