For those that have worked in museums, libraries, and other specialty civic projects, you may have noticed the tendency for architects to use 2# MLV, or 2 lb/sf (2 pounds per square foot) Mass Loaded Vinyl. This is an extremely heavy soundproofing membrane that is used to block noise from loud areas, such as mechanical closets or electrical rooms, from penetrating into quieter areas.

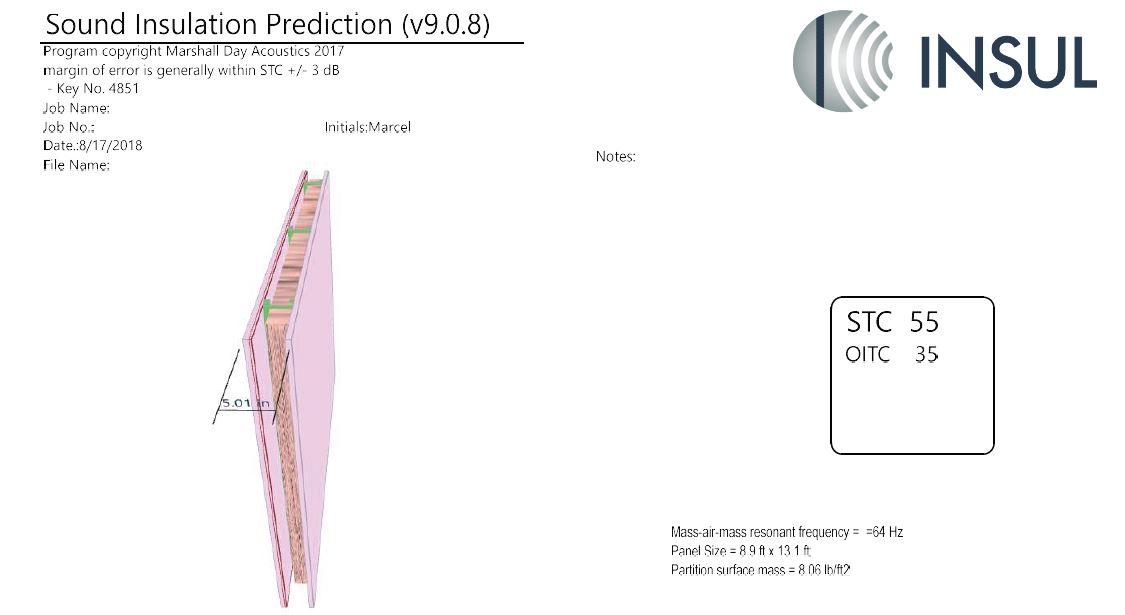

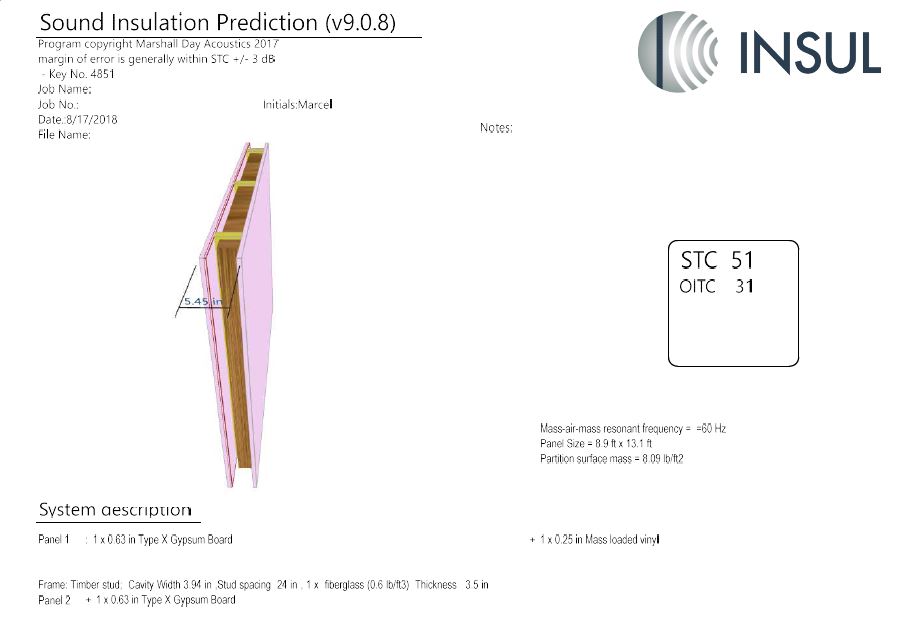

While not as cost-effective as the Wall Blokker soundproofing membrane, 2 lb MLV does have good low-frequency performance for vibrating and reciprocating equipment. This can come in handy in frequencies below 500 Hz, when increased attenuation is required. See the INSUL model below for its STC performance on a single-stud wall. An added benefit of using a single one-pound sheet is that, while the cost may increase, there may be some schedule savings due to the single layer. For projects with significant schedule constraints, this may be the best option.

Applications for 2 Pound Mass Loaded Vinyl:

- Single Stud Walls when there are significant schedule constraints

- Mechanical areas needing low-frequency attenuation

- Museums, Libraries, and other civic projects

Difference between 1 lb and 2 lb Mass Loaded Vinyl:

Many contractors and architects want to determine the cost-benefit between going with a 1 lb MLV versus a 2 lb MLV product. Why not just staple up two layers of 1 lb material, if there’s no improved performance?

For starters, the weight difference is evident. 2 lb mass loaded vinyl is twice as heavy as 1 lb. These weights are often “nominal” so that 2 lb MLV actually weighs approximately 1.8 lbs/square foot (and 1 lb MLV actually weights 0.9 lbs/square foot).

The thickness also changes in equal proportion. Rather then 1/4″ thick, 1 lb Mass Loaded Vinyl is 1/8″ thick. The density of the material does not change, so it is the thickness of the extrusion that is actually driving the weight change.

One major benefit of installing a single sheet of 2 lb MLV is that the labor cost is significantly reduced (rather than double-installing standard-weight product). If an STC of 50+ is needed on wood stud assemblies, or 60+ on metal studs, 2 lb mass loaded vinyl is often the most cost-effective approach.

Alternatives to Mass Loaded Vinyl:

There are also a number of substitutes for Mass Loaded Vinyl. One of the biggest complaints is off-gassing. MLV, due to its base Vinyl polymer, is naturally rigid. Chemical additives are put in called “plasticizers” that make the material flexible. However, over time these plasticizers tend to migrate out, resulting in off-gassing that makes the material rigid and sometimes produces a noticeable odor.

When considering using MLV, also review the safety information, usually included on the Material Safety Data Sheet. When it is enclosed behind drywall, there is limited safety down-side to using the product. However, the hardening side-effect may deteriorate the product over time from an acoustic perspective.

Summary – When to use 2 lb Mass Loaded Vinyl:

When MLV is specified, it is difficult to opt out of it. When this is the case, consider using an EVA-based mass loaded vinyl material that does not off-gas and has better acoustical properties. In loud mechanical rooms or in sensitive spaces, such as libraries or museums, the use of heavy Mass Loaded Vinyl may be an ideal application to prevent unwanted noise intrusion. Using 2 lb Mass Loaded Vinyl greatly improves the STC (or soundproofing performance) of the wall, and can be much more cost-effective than moving to CMU or triple-layering drywall.