Mass Loaded Vinyl continues to be a leading product for enhancing STC in partitions, particularly in the residential, multi-family, and hospitality sectors. Thinner than drywall, and much more effective at blocking sound transfer, EVA and PVC Noise Barriers both provide significant improvement in wall soundproofing levels. However, which one is right for your project? Consider the pros and cons of each Mass Loaded Vinyl category below.

MLV Sound Barrier Uses

While Mass Loaded Vinyl, also called MLV, has been a dependable and competitive product to improve STC in industrial settings for decades, there has been little improvement in the product itself in recent years. As we’ve discussed before, Mass Loaded Vinyl is a PVC-based product that adds a cheap filler, usually Calcium Carbonate or Barium Sulfate, to provide superior sound ratings. The initial versions of MLV sound barrier included Lead as well but was replaced over the years due to health concerns.

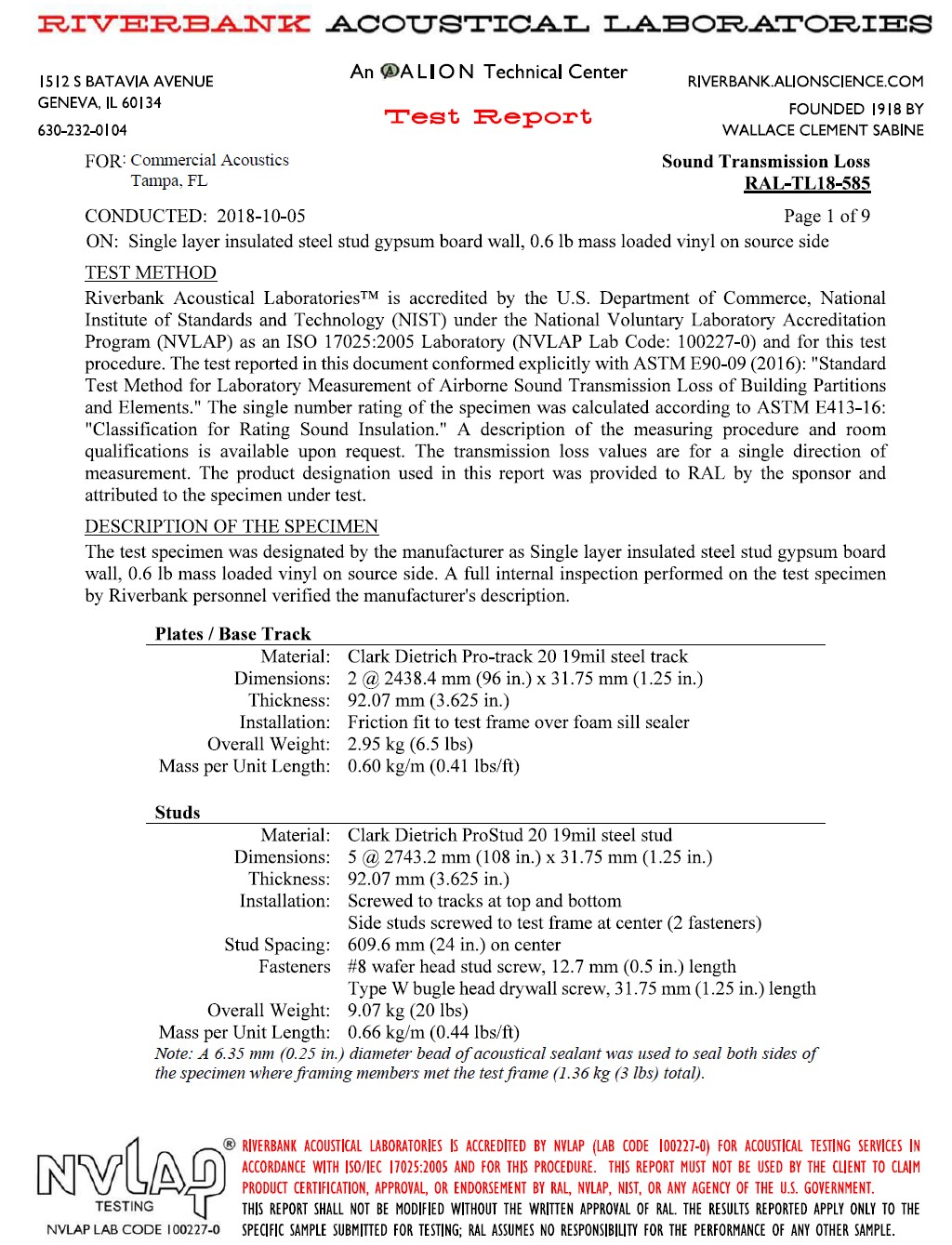

Mass Loaded Vinyl Specifications

Types of Mass Loaded Vinyl

The focus on MLV sound barrier product development has been on how to make the product cheaper, and thus more applicable to residential and commercial settings. This has led to a number of improvements in manufacturing and a search for cheaper filler alternatives.

However, the PVC-base of the product has not changed – until recently. After several years of product development, followed by 18 months of fire and acoustical testing, Commercial Acoustics has developed an EVA-based Mass Loaded Vinyl soundproofing membrane that has improved the performance without sacrificing cost competitiveness.

One major difference is that PVC is a naturally rigid material (think exterior panels for housing or fences). In order to make it flexible, you need to add a softening agent, known as a “plasticizer”. The downside of this is 1) added cost, and 2) the plasticizer migrates out of the product over time, causing the PVC to become brittle. This is why older plastic toys break easily if left outside for a few weeks.

Benefits of Using MLV Sound Barrier

While Wall Blokker is equally heavy as other types of Mass Loaded Vinyl, the improved flexibility also improves the sound-blocking capacity, on both Wood and Metal stud walls. When using Wall Blokker or other MLV types on Wood Studs, you can achieve the best results when also using RC, or if the Wood Studs are staggered.

Whether you decide to go with an EVA or PVC-based Noise Barrier, using MLV as opposed to multiple layers of drywall is typically always the best option. Along with the cost savings achieved when using MLV instead of extra drywall layers, MLV also provides schedule savings with it’s speed and ease of installation.

Regardless of your needs, Commercial Acoustics has years of experience installing Mass Loaded Vinyl and Wall Blokker products, to offer our a clients a full range of solutions for their unique problems.

Summary – EVA vs PVC Noise Barrier

Although PVC mass loaded vinyl is an acceptable and effective product, and normally the basis of design, it comes with some downfalls when compared to an EVA based mass loaded vinyl.

- Most PVC Noise Barriers cost more per square foot when compared to Commercial Acoustics’ EVA-based MLV (Wall Blokker)

- EVA Based mass loaded vinyl has a longer life cycle than PVC based mass loaded vinyl. Over time, PVC Based MLV will become brittle and break due to the harsh plasticizers used during production.

- Unlike PVC Noise Barriers, EVA-based noises barriers do not off-gas any chemicals or offensive odors.

- Since EVA-based MLV is more flexible than PVC-based MLV, it actually has better soundproofing abilities, and can result in better STC ratings in the same wall assembly.