When you see “Wall Covering”, or WC, in an Architectural Drawing Set, it can be interpreted or defined as a few different things. We often see Wall Coverings, Acoustical Wall Coverings and Vinyl Wall Coverings, and even Stretched Fabric Wall but what makes each one of these products unique?

How is a Stretched Fabric Wall Constructed?

Stretched Fabric Wall is made up of 3 components:

- Track

- Fiberglass

- Fabric

When installing fabric wall, the track is fastened to walls with staples, and fiberglass is fastened with nails, otherwise the fabric will hold the fiberglass in place. Fabric wall core is most commonly available in 1″ and 2″ thickness, it’s also available in 4″ thickness along with some other custom thicknesses (often 1.5″ or 2.5″).

Additionally, the fiberglass core is available with a standard face, white-mat face, or impact resistant facing. Standard fiberglass is 6 pcf throughout, and there’s no special treatment to the face of the material. White-mat faced fiberglass is also 6 pcf throughout, but there’s a thin white polyester layer on the face of the material. This is typically used to prevent the bright yellow color of the fiberglass from telegraphing through white and other light-colored fabrics. Lastly, impact resistant fiberglass is 6 pcf throughout, with a 1/8″ thick layer of 16-17 pcf fiberglass laminated to the face.

What Thickness Fabric Wall Should You Specify?

When considering the thickness of a stretched fabric wall, it’s important to consider the use for the space and its target reverb time. The most common noise reduction coefficients (NRC) can 0.80 and 1.05 for 1″ and 2″ thick fabric wall, respectively. The NRC of a product measures the percentage of sound waves that it can absorb, so 0.80 NRC means 80% sound absorption and 1.05 NRC means 100% sound absorption.

For example, it’s common to use 1″ thick fabric wall in smaller conference rooms, corridors, offices and other spaces that might not need significant treatment. Typically large spaces need more significant acoustic treatment, since they tend to have higher reverb times. 2″ thick fabric wall is often used in large auditoriums and classrooms, and gymnasiums.

Another characteristic to consider besides thickness is impact vs non-impact fiberglass. Impact fiberglass, also known as tackable fiberglass has a 1/8″ thick 16-17pcf facing laminated to the standard 1″-2″, 6 pcf layer. This is really only necessary in gymnasiums or where the structed fabric wall is low on the wall, and in high traffic areas.

Finished Fabric Wall Appearance

Once finished, a stretched fabric wall will have visible seams. Seams are unavoidable with fabric walls due to the center track that’s required between sections. At some point the fabric has to be tucked since a roll is only anywhere between 54″-66″ wide. As long as seams are equally spaced, fabric wall is still an aesthetically pleasing finished product.

Read More: Fabric Wall Track Profiles & Details

Different track profiles also allow fabric wall to have a more unique finished look. Some of these profiles include square, beveled and radius.

What is an Acoustic Wall Covering?

Acoustical wall coverings are more similar to wallpaper if you had to compare it to something. However, rather than being made of paper or vinyl, they’re made of compressed polyester. Unlike typical wall papers and other non-acoustic wall coverings, acoustic wall coverings are anywhere between 3 mm and 5mm thick (1/8″-1/4″ thick).

An acoustic wall covering is made up of one main component, and that is the wall covering itself. Acoustical wall coverings also require adhesive, as opposed to a stretched fabric wall where the fiberglass core is held in place by the fabric. For a wall covering to be considered acoustical in nature, it must have a noise reduction coefficient, or NRC, which rates the percentage of sound waves it will absorb vs reflect.

What Thickness Acoustic Wall Covering Should you Specify?

Because polyester wall coverings are so thin, they have minimal acoustic performance – only about 0.4 NRC depending on the thickness, but will be below 0.8 NRC (1″ thick fabric wall NRC). Any thickness of wall covering from 1/8″-1/4″ makes such a minimal impact on room acoustics, it really doesn’t matter which thickness is specified.

Different brands have different color and patterns available, so let the aesthetics of the wall coverings influence your decision rather than the thickness.

Finished Acoustical Wall Coverings Appearance

Once a wall covering is hung, whether it’s acoustic or a standard vinyl wall covering, there shouldn’t be any visible seams. If there is a pattern, it should line up between each run of the wall covering to make any otherwise visible seams, invisible. Wall covering sheets can be butted up to one another to reduce the appearance of seams as much as possible

In Conclusion – Stretched Fabric Wall vs Acoustic Wall Covering

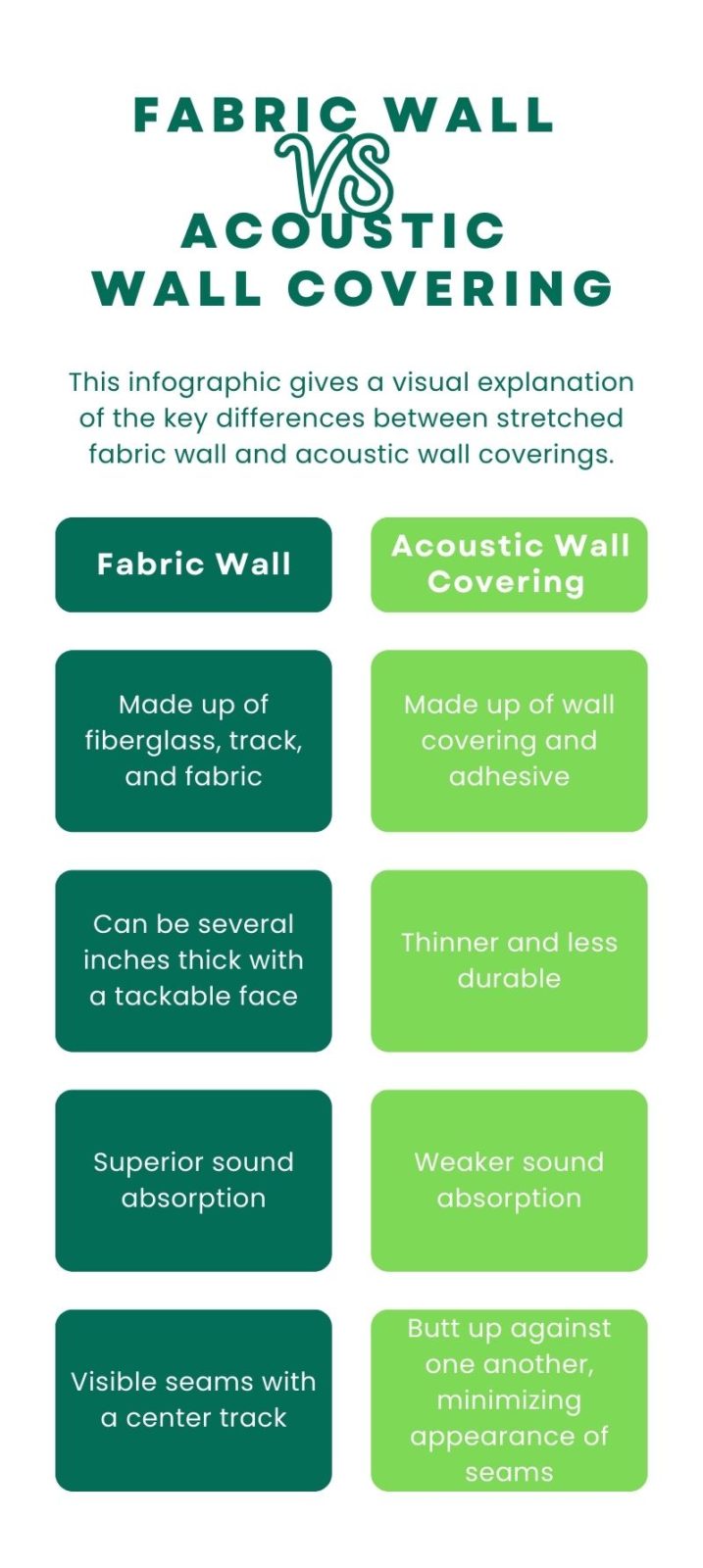

There are a few main differences between Stretched Fabric Wall and Acoustic Wall Coverings:

- Components – Fabric Wall is made up of fiberglass, track and fabric, while a wall covering is just the wall covering and its adhesive.

- Available Thicknesses: Fabric wall can be 1″, 2″ and even 4″ thick, and allows for the options of a tackable face. Wall coverings are much thinner and less durable.

- Acoustic Properties: Fabric wall offers much superior sound absorption properties compared to an acoustic wall covering.

- Finished Appearance: Fabric wall has visible seams due to the use of center track, while wall covering sheets butt up against one another to minimize the appearance of seams.