Similar to wall soundproofing the sound traveling through floors is dependent on structure-borne and airborne noise. These two transmission mechanisms should be addressed in tandem to ensure that the maximum amount of noise transfer is attenuated. Unlike walls, flooring is often-times a major contributor for structure-borne noise, due to the constant footfall or impact imparted on the floor from moving objects (unless of course, someone is hammering into the wall.) This is particularly problematic in high-rise condos and apartments, and sometimes even in 2-3 story homes. Consider the following ways when determining how to Soundproof a Floor to achieve an acceptable IIC – Impact Insulation Class.

Floor Soundproofing Layers – How to Increase IIC between Floors

First, evaluate the flooring system to determine the primary paths of sound transfer. Once identified, we always address the “low hanging fruit” first – those elements that are fixed in the most cost-effective manner. Finally, determine the amount of sound-blocking you need in the floor, and develop a budget that will allow you to meet those goals. Solutions range from decoupling joists from subfloors, adding soundproofing layers below the top floor, and even using localized isolation pads for loudspeakers and dancing areas.

RELATED: See Soundproofing Materials for Floor Soundproofing

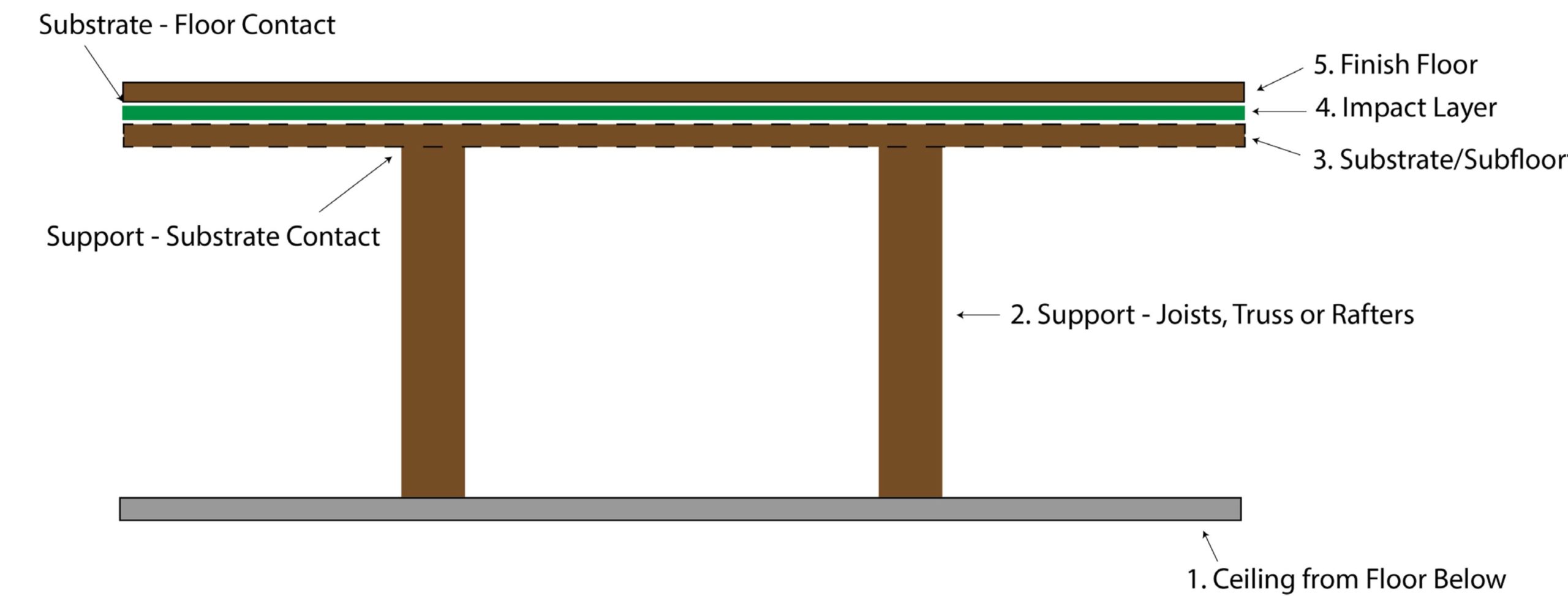

There are 5 primary layers in any floor, as well as two primary contact points, show in the diagram below,:

- Ceiling Below – while rigidly mounted gypsum ceilings may provide a minimal IIC improvement, adding a resilient channel and resiliently-mounting the drywall may add between 7-10 points. This is a necessity for most wood joist/web truss assemblies if they hope to achieve IIC 50.

- Floor Supports – The rafters or joists running within a floor to support it from caving in or sagging when a load is applied. These are often 10″ boards of construction lumber or 18″ deep open web truss, installed so that their greater dimension is vertical to more effectively combat bending moments. Wood joist, TJI, and Wood Truss all have similar IIC performance, which are each much lower than concrete STC or IIC ratings.

- Substrates – also known as a subfloor, this is the layer installed directly onto the underlying floor supports. It is not the aesthetic layer that you can see when walking into a room, but provides support and additional insulation. Generally OSB and Gypcrete for web truss systems, or just the poured concrete, composite slab, or hollow-core plank for concrete systems.

- Flooring Underlayments – the acoustic layer is sometimes included in flooring, especially when there are sound-blocking or absorption requirements. These may range from cork board and carpet cushions to specialized acoustical sound-blocking materials (including our Floor Blokker). While cork board may be effective at reducing some vibration, acoustic floor underlayments provide sound-blocking for structure-borne and airborne noises.

- Top Flooring/Finish Floor – the top flooring layer is the aesthetic and functional layer that you see when entering a room. This can range from wood (hardwood, engineered wood, parquet mosaic, or bamboo) to concrete, carpet, or tile. Carpet has a much higher IIC than other floor finishes, while ceramic or porcelain tile generally transmit the most sound.

The performance of any flooring assembly depends on the interaction and makeup of each of these layers, and the contact points between them.

Floor Soundproofing Interfaces

There is a contact point between each layer. With 4 layers, that leaves three primary contact points (we have consolidated the substrate-acoustic underlayment-top flooring below), listed as follows.

- Floor Support-Substrate Contact: the substrate is typically screwed directly into the supports, ensuring a structural contact directly between the two layers. This contact allows structure-borne noises to flow directly through the assembly, and may be minimized by using a non-hardening caulk or strips of acoustical underlayment between them.

- Substrate-Top Flooring Contact: There is also an opportunity to decouple the connection between the substrate and top flooring layers, via use of non-hardening caulk or thin-set adhesive membranes (when the top floor can be adhered, such as in the case of hardwood flooring or tiles).

Floors have a number of unique performance characteristics from other construction elements, implicit in their function to support weight above them. These include:

- Thermal: act as a temperature gradient between the room and underlying space

- Moisture: this is critical on the 1st floor or at grade-level. Non-permeable, moisture-resistant materials should be used to ensure moisture does not seep into the living space. The primary difference between the Floor Blokker and other wall and ceiling sound-blocking materials is its moisture-resistant properties.

- Acoustics: as mentioned below, flooring not only provides a substantial STC from tenants above and below, but is also responsible for IIC floor soundproofing (structure-borne). Unlike walls and ceilings, carpeted flooring can also significantly contribute to absorption in an open space.

- Structural Support: As we’ve already discussed, the flooring also needs to support weight from above, evenly and uniformly, without excessive deflection. To reduce creaking below, it’s critical to ensure the floor is level (i.e. less than 3/16” vertical change every 10’). Acoustic underlayment or non-hardening caulk may be used to “shim” the floor to approach this level criteria. Furthermore, plywood and other underlayment should be “scored” or “kerfed” during install, to release tension and prevent warping.

Generally speaking, when looking to improve the sound-blocking capability of a floor, we are looking to improve its ability to block structure-borne noises (shown in its IIC rating) and air-borne noises (shown in its STC rating). Floor are unique in that IIC is more important than most other structural elements. This is due to frequent impact noises they endure, from footfall and support moving objects (unlike most walls and ceilings, that do not receive regular impact). To improve the STC of the floor, we increase the mass of the floor by adding additional, functional layers, and the IIC by decoupling adjacent layers and adding impact-resistant materials.

Approach each layer independently, adding thickness to plywood, gypsum board and concrete wherever possible. Add decoupling between joists and subfloor, and then between the subfloor and top floor. Finally, add a reliable acoustic underlayment that will increase both the IIC and STC of the floor. Acoustic underlayment should be installed under framing (if necessary) on the floor above, and should completely cover the floor so that paths of least resistance do not develop.

A typical IIC for high-rise construction is 50, meaning that the floor reduces structure-borne noise by 50 dB on average. By applying the Floor Blokker, decoupling joists and sub-floors, and using other techniques discussed above, you can achieve and exceed IIC values of 60 or more.

Best Soundproof Underlayments

The best soundproof floor underlayments work to improve both the STC and IIC rating of a floor-ceiling assembly. In other words, a good soundproof underlayment should help to improve sound blocking for both structure-borne and airborne-noise.

High-end floor underlayments are made using either mass loaded vinyl or crumbled rubber. A good underlayment blocks air-borne noise with its mass and its ability to decouple the finished floor from the subfloor, which helps to stop sound in its path through rigid surfaces. A good soundproof underlayment will also block structure-borne noise in a similar way, the underlayment acts as a shock absorber for structure-borne noises such as footfall.

When selecting the right sound mat, be sure the one you pick is suitable for use with your selected finish floor.

Floor Soundproofing Checklist

- If there is a ceiling below (not exposed concrete deck), ensure that it is resiliently-mounted to the bottom of the flooring assembly. This is a critical way to pick up 7-10 IIC points. Do not allow Hat Channel (or H Channel). RC-Deluxe or another IIC-rated resilient channel are designed to improve the floor’s IIC rating.

- Put some batt in the flooring cavity. These is little benefit to any batt insulation thicker than 2-3″. However, some batt insulation will reduce reverb in the cavity, and thus, sound transfer through the assembly.

- If using concrete, ensure thickness is at least 6-8″. Thinner concrete slabs may need a gypcrete topping for increased depth.

- Select Finish Floor: porcelain/ceramic tile transmit the most structure-borne noise, while carpet on a thick pad transmits the least. If using LVT, strongly consider using a high-performance brand (as quality greatly varies), and ensure it is 5mm or thicker.

- Select a flooring sound mat that, when used in conjunction with the rest of the flooring assemblies, meets or exceeds your target IIC rating.