Zoo Tampa at Lowry Park was remodeling their new sponsor room, for the entertainment of their sponsors when they attend events at the zoo. They planned for a grand entry room featuring an AV presentation welcoming the donors to the zoo. However, the room they were converting, finished with drywall and tile floors, lacked any […]

Author Archives: Acoustics Expert

Gulf Coast Bank’s contractor contacted Commercial Acoustics to install an acoustic fabric wall system in the bank behind their small offices for reverberation mitigation and act as the finished back walls of their offices. The remodel plans called for a fabric wall with the seams matching the cabinetry. Fabric Wall in Banks to Reduce Echo […]

Bank of America in Jacksonville, Florida was renovating one of their banking and customer service locations when the General Contractor contacted Commercial Acoustics to provide a bid for sound masking systems within the space. Like many banks and financial institutions, BOA determined that speech privacy in the space was critical to maintain confidentiality of financial […]

Sound Masking systems are best used in open areas where distracting noises can make it difficult to focus or relax. This is commonplace in open offices and bullpens, as well as call centers and libraries. Sound masking provides speech privacy in the space, so that employees can focus in the office without annoying and distracting […]

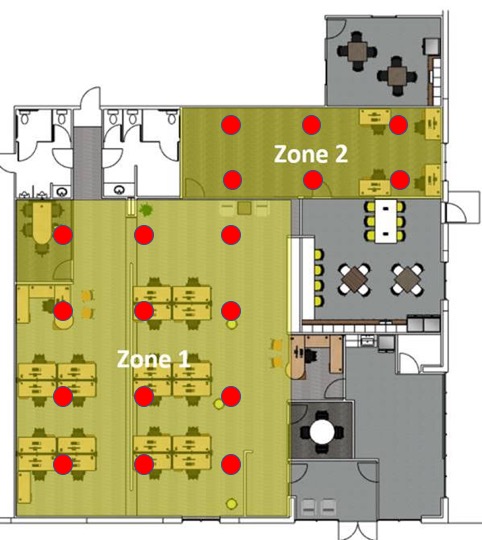

A common question we get everyday is where to place the acoustic panels once you’ve purchased them. Whether you have acoustic ceiling clouds, art-wrapped acoustic treatment, or standard fabric-wrapped acoustic panels, by spacing and installing them properly, you can greatly improve the efficiency and aesthetics of your space. Acoustic Panel Placement Guidelines Our trained and […]

Courtrooms are critical civic locations that allow our society to operate. Courtrooms rely on communication, and without it, court cases and proceedings may not run smoothly or effectively. By knowing when and how to apply various acoustic treatments to courthouses, you can allow clear and comfortable speech and promote stronger communication. It’s important to have […]

Sound Absorbing Panels can be an excellent option when you have excessive reverberation or echo within a closed space. These multi-functional treatments can be hung on walls or ceilings to absorb sound waves, making speech more intelligible, and improving acoustical comfort. However, absorbing panels are not effective if the primary issue is sound transmission from […]

Every project is unique. Even if there are acoustical requirements, certainly many projects will not require the detailed review of an acoustic consultant. However, not using a consultant can be more costly than hiring one, especially if there are noise complaints and post-tenant modifications or retrofits needed to fix these issues. Learn when hiring an […]

Here’s a question we get everyday: White noise vs pink noise – what’s the difference? Sound masking systems are often described as “white noise machines” or “pink noise speaker systems”, when in reality they are approximated as a blend of both. White noise is the same sound intensity at all frequencies, while pink noise decreases […]

731 St Charles Ave. is a $40 million condominium development currently under construction in the heart of the CBD in New Orleans. The site was renovated to replace a historic concrete building from 1965 that threw several of the city’s earliest Mardi Gras balls. Luxury Condo Soundproofing The five-story development boasts luxury units that range […]