Movie theaters have a particular type of challenge when it comes to soundproofing and acoustics. The biggest issue many theaters face is low-frequency sounds penetrating through auditorium walls and disturbing guests. This is especially true in luxury cinemas where guest comfort and sound privacy is of the utmost importance for repeat business and satisfied online reviews. While an STC of 65 may be sufficient to hit THX and other industry-specific requirements, it does not go nearly far enough in its focus on low-frequency attenuation. (Imagine trying to watch “The Notebook” with “Mission Impossible” playing next door. Those low rumbling explosions, around 63 Hz, will bleed through a wall and be easily heard in a theater with low background noise).

With today’s common construction methods, a typical answer to low-frequency sound transmission is to add multiple layers of drywall to an auditorium partition. Although more Mass is added to the wall with this construction, the result is diminishing returns with each layer of drywall added due to the stiffness of the drywall itself. For a much more cost-effective approach, we’ve had success implementing the Wall Blokker soundproofing membrane.

Soundproofing Cinema Walls – STC 65+

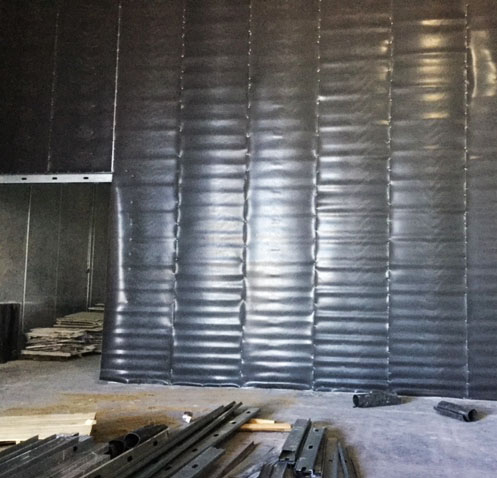

Commercial Acoustics was contracted to improve acoustics for the Cinepolis cinema chain nationwide. By analyzing the architectural drawings and testing various assemblies at Riverbank Acoustical Laboratories, Wall Blokker was the chosen product to achieve a high STC partition while also reducing construction schedule and costs. Instead of using multiple layers of drywall, Wall Blokker soundproofing membrane was added to both sides auditorium partitions.

The resulting assembly of 1 layer of drwall on each side with one layer of Wall Blokker on each side achieved an STC improvement of 6 points, while also exceeding Transmission Loss of 32 dB at 63 Hz, a significant improvement in sound attenuation at the critical low frequency range.

Both the flexibility of the Wall Blokker membrane and it’s 1 lb/sf Mass provided improved sound quality within their auditoriums. Commercial Acoustics also custom-manufactured the membrane to the 33′ deck height, eliminating cutting and added waste in the field. By moving to Wall Blokker, 3 weeks of construction schedule were saved as installation was faster and less labor-intensive than drywall-only assemblies.