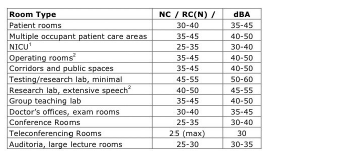

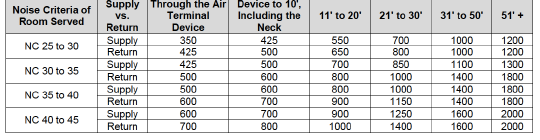

NC, or Noise Criteria, is the background noise level attributable to HVAC and other background mechanical noises. In certain spaces, it is important to reduce this NC level so that sounds are clearly heard. This is common in theaters and cinemas where background noise may impair the ability of attendees to enjoy the show/performance.

NC levels are limited by a number of factors, including distance from the air handler and other noisy system components, equipment selection, and speed of the air through vents and ducts.

Composite Noise Calculations

Composite Sound Levels are calculated by combining the STC of the individual components. For instance, if a wall is 50% brick and 50% glass, then the composite STC of the wall will fall between the STC of a brick wall (approximately 40) and the glass (approximately 20). The STC is weighted heavily toward the lower of the two numbers. You may assume that the STC of the described wall is 30 (half way between 20 and 40). However, the actual composite STC of the wall is 23.

Similar to 1% rule, sound follows the path of least resistance. This results in the majority of sound transfer passing through the glass. The composite STC may be calculated as follows:

Equation: Composite TL = 10log (SumS/Sum[tS])

This explains why exterior windows should always be improved prior to investing any STC improvement in exterior walls.

Exterior Noise Propagation

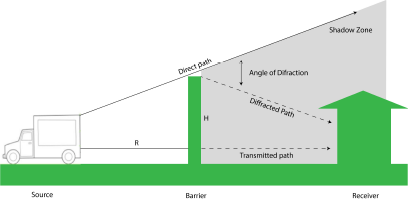

A common question that acoustic consultants have to solve is how high a wall needs to be to block the sound. This is a combination of several factors – the thickness of the wall, the frequency of the sound, and how much needs to be blocked. As discussed earlier, a reduction of 7 dBA is significant and reducing by 10 dBA represents halving the perceived sound level.

Example: A truck backs up to loading docks for delivery at 6 AM every morning, near a hotel. The hotel owner is making noise complaints due to the early deliveries and upset guests. In order to meet the guests’ expectations, it is agreed upon that a 7 dB drop at the 500 Hz truck beeper frequency range will be acceptable.

The barrier is to be installed 10’ from the loading dock. How tall does it need to be?

Equation: TL = 10log(H2/R) + 10logf ‐ 17

7 = 10log(H/102) + 10log(500) – 17

H=3.2’ (Above the Line of Sight)

Vibration Paths

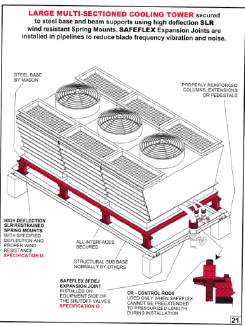

Vibration issues are a common complaint when heavy machinery or loud thuds are a problem. Treating vibration issues can be difficult, since there are often structural requirements to ensure that equipment is properly supported. However, rigid structural supports can result in free vibration through the steel, concrete, and other structural members.

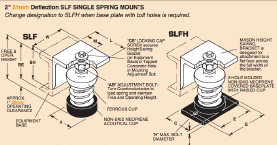

First floor isolation may be achieved with the use of slaw-‐cuts in the slab. This breaks the monolithic connection between the equipment and prevents vibration travel to adjacent spaces. Further, vibration pads, mounts, and springs may be used to isolate vibrating equipment.

If unsure of the amount of vibration isolation needed, vibration testing may be completed with the use of uni-‐axial (up and down) or tri-‐axial accelerometers. These are instruments that create electric currents when moved, and by doing so, can measure the amount and time of subtle vibrations.