Find Basic Tips for Reducing Mechanical Noise

There are a number of mechanical systems in nearly every building that can cause annoying hums, drums and vibrations. Unlike traditional soundproofing and absorption techniques, these are dependent on a number of other characteristics innate in the machine’s operation – including size, frequency, and mounting conditions.

Treating a mechanical system can be a difficult task and requires a custom approach for each system. However, there are certain elements that are common in most mechanical noise situations, and we review them below.

Motors & Fans Noise

It is common for motors and fans to transfer their vibrational energy to the slab below.

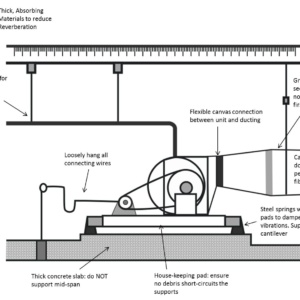

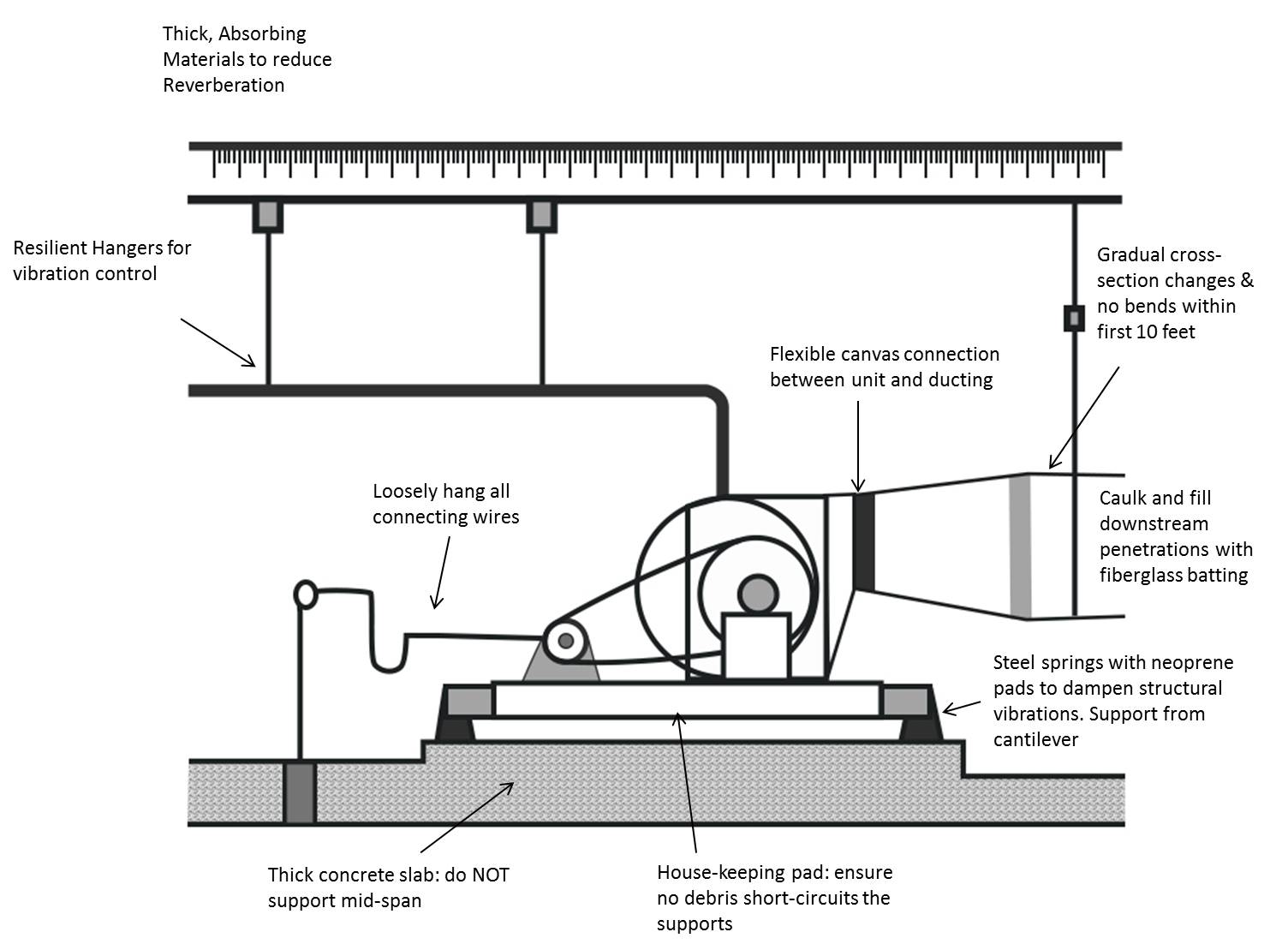

Motors and other heavy equipment should be mounted on a resilient surface that helps to absorb the vibration as it works. Resilient mounts may include neoprene pads with steel base plates, or ribbed rubber for lower weight applications. Even cork may be used when the weight is extremely low.

See Case Study: Acoustic Consulting for HVAC Noise

Cross Talk – Noise Issues through Ductwork

This annoyance occurs often with ducted or plenum returns that connect directly between 2 offices. This happens regardless of direction of airflow, since the sound can travel almost as easily upstream.

You should be sure that the static deflection of the resilient mount does not exceed its maximum threshold, or it will no longer be effective.

See More Information about Drop Ceiling Noise Issues

Acoustic Treatment for Air Handlers

Resilient mounts should be used under a baseplate that equally supports the weight on all four sides. Where possible, the baseplate should extend beyond the equipment such that the vibrational mount is cantilevered.

Loud motors that approach the levels acceptable by OSHA for cumulative exposure may be handled by building a small “Room Within a Room” (RWAR) directly around the noise source to isolate it. This typically consists of a steel enclosure with walls lined with fiberglass absorption material.

TIP: Be sure to use flexible connections at the Air Handling Units and duct connections so that vibration may be isolated to sections of the duct system.

Ducts & Pipe Noise

When there is “breakout” noise (sound escaping from a pipe or duct), use duct lagging to increase sound-blocking in the duct itself.

Fiberglass absorption materials and vanes inside the duct work to reduce turbulent flow, which often leads to excess noise. This may also be controlled by properly sizing the ducts to keep airflow speed at medium to low thresholds.

Ducts commonly create structure borne noise when they are supported by walls and ceilings. To alleviate this issue, simply pack wall openings with batting and caulk the opening closed. Use resilient hangers to support the duct from ceilings to ensure the vibrations do not transfer into the slab above.

For sound that continues to come through the ductwork, a muffler placed directly downstream of the fan will greatly reduce turbulent airflow further.