Resilient Channels, sometimes abbreviated as RC or Z Channel, are some of the most common components installed on projects requiring additional soundproofing (higher STC ratings). While they provide a significant improvement in decoupling the structure-borne noise in walls, they should not be seen as a panacea for all noise issues. Over the past 20 years, in both industrial and commercial settings, we’ve found resilient channels installed correctly in the field less often than not, resulting in poor acoustical performance. Below is a list of most common design and installation failures.

While Resilient Channel can provide adequate options with careful Construction Administration and avoiding the pitfalls below, it provides its STC improvement only by decoupling the drywall from studs beneath. Mass Loaded Vinyl, on the other hand, increases STCs by decoupling the drywall from the studs with a thin, flexible layer, but also adding mass to the wall, which further improves the STC (by as much as 3-4 additional layers of gypsum). In some stiff walls (single wood stud), a combination of approaches may make sense. Nevertheless, by avoiding commons mistakes made RC design & installation, the overall soundproofing performance of the wall may be improved.

Common Mistakes with Resilient Channel

Designing Resilient Channel for Metal Studs

The #1 benefit of Resilient Channel is the ability to decouple structure-borne noise at a reasonable cost. This is an effective approach on wood stud or high-mass walls with a high stiffness index. However, a significant amount of commercial construction is completed with 20-gauge or 25-gauge steel studs, which already do an adequate job decoupling noise due to their intrinsic flexibility. The proper soundproofing method with these walls is to add mass via a soundproofing membrane or conventional construction materials, since additional decoupling will result in very little or no further improvement.

Cost-Effective Alternatives to Resilient Channel

Click here to request a review of your Resilient Channel Assembly

Determine STC Rating of an assembly – With and Without Resilient Channel

Poor Installation Methods – Most Common Problems with Resilient Channel Installs

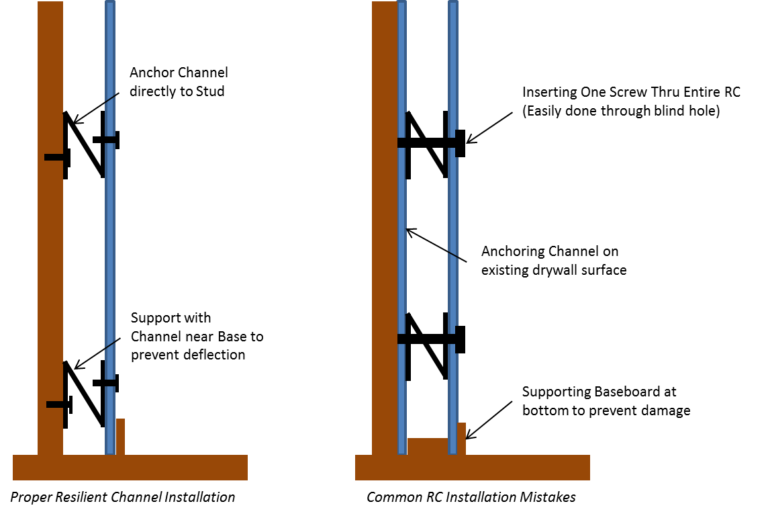

The most common cause of failure of this system to meet performance specifications is lack of proper installation in the field. Resilient Channel is often installed by the same drywall hanging team that performs the rest of the drywall installation, in an effort to cut cost and reduce schedule. Without a professional that is very familiar with this, it is easy to run into the following issues.

- Drywall Screws Going Into Both Resilient Channel Flanges: This needs to be inspected after every sheet of drywall. The RC is designed to have one screw lock it into the stud, and another screw attaches the 2nd flange to the drywall. However, the channel is not visible when screwing in, so it is very difficult to attach the fasteners to the exact spot. If any of the screws go through to the inside flange, the Resilient Channel is now fully locked in, and provides no soundproofing benefit.

- Baseboards: When installing baseboards, many contractors place a wooden block to reinforce the bottom edge of the drywall. If this is done, the drywall is structurally locked to the studs, and the RC is not effective.

- Hanging RC Over Existing Drywall: When adding a 2nd layer of drywall, this should be done on the other side of the wall. If the resilient channel is installed directly over drywall (rather than studs), it creates a mass-air-mass condition that greatly reduces its effectiveness.

- Resilient Channel Spacing: Note that all of the lab test data with RC is based on 24″ on center. However, in the field, it is difficult to keep this spacing consistent. Ranges over 24″ are against the installation instructions, while spans less than 24″ ensure that the Resilient Channel will not be as effective as it is in the lab.

- Using the wrong type of Resilient Channel: RC (also known as Z-channel, because of its shape), is a very different animal than Hat Channel (or H-Channel). While Resilient Channel can improve the STC of a wall by several points when installed correctly, hat channel provides almost no improvement, and should be avoided AT ALL COSTS on STC-rated assemblies.

Attaching Cabinets or Bookshelves

Although strong in compression, RC is very weak in tension, and therefore should not be used on walls where heavy units will be mounted, such as TVs, cabinets, or bookshelves. These units will either pull away from the wall over time, or if directly mounted to the studs, will greatly reduce the effectiveness of the Resilient Channel. When a screw mounts directly through the resiliently-mounted drywall and into a stud, the RC is “grounded”. Just a few grounded screws will compromise the integrity of the entire resiliently-mounted wall.

As a rule of thumb, Resilient Channel assemblies should always be field-tested to ensure they perform adequately in the field. Due to complex installation requirements and mounting restrictions, field performance often deviates from lab-tested STC ratings.

Using Resilient Channel in Tight Space Confinement

Finally, RC requires an extra 2” per room used, due to the thickness of the channel and the extra sheet of drywall. In restricted spaces, this often becomes a limiting factor, especially in renovations or small units. However, don’t be tempted to over-torque your fasteners in an effort to shave off a 1/4″ here and there. Resilient Channel only improves the STC rating by providing that decoupling layer, so the flimsy, ungrounded flexibility is critical for its performance.

Deciding on Resilient Channel vs. Soundproofing Membrane

Ultimately, every architect needs to determine their STC requirements and the most cost-effective way to meet them. As an acoustical consultant, we typically recommend RC for gypsum ceiling assemblies under open web truss and concrete decks, since resilient channel can be extremely effective on ceiling assemblies. Furthermore, we’ve found it to be quite effective on walls requiring 2-hour fire ratings that do NOT require heavy loads suspended on them (anything over 50 pounds). In hotel rooms or apartment complexes, adjoining walls should strongly consider a range of soundproofing membranes that best meets their needs, often at a significant cost reduction from RC while still hitting higher dB losses.