Below find an excerpt of a Consulting Case Study in which Commercial Acoustics provided Acoustic Consulting Services to a commercial client to identify and mitigate vibration issues in their concrete slab.

Vibrational Testing Scope of Work:

A property management firm has encountered complaints regarding structural vibrations in one of its commercial office properties in Lake Mary, FL. Specifically, occupants complain of annoying or distracting vibrations in the concrete slab, and some occupants have been concerned with potential structural integrity issues.

The property management firm has already hired a structural engineer to inspect the structure and found no safety issues. The engineer has suggested that the vibrating slab may be due to under-loading of the slab, since all of the occupants have not yet moved in, resulting in a lighter-than-designed live load. This results in serviceability issues due to footfall in certain areas.

Commercial Acoustics performed a vibration study to determine the root cause of the unwanted vibration, and whether the structure complies with ISO 10137 Standard vibration serviceability criteria.

NOTE: The criteria assesses only whether the structure complies with vibration related to serviceability and NOT for safety.

Vibration Testing Findings

Testing was performed per ISO 10137 “Bases for design of structures – Serviceability of buildings and walkways against vibrations”.

Three uni-axial accelerometers were used to measure the vertical vibrations incurred during a standard work day on the 3rd floor of their building. The sensors were placed initially at workstation 4183, which was the location of one of the chief complainants. The complainant was also present at the time of the testing and noted that she takes motion sickness medicine throughout the day to prevent nausea.

It should be noted that certain individuals are more sensitive and susceptible to vibrations, even if these vibrations are beneath commonly-accepted levels, and our mitigations list some areas in the office that may be more acceptable for those employees.

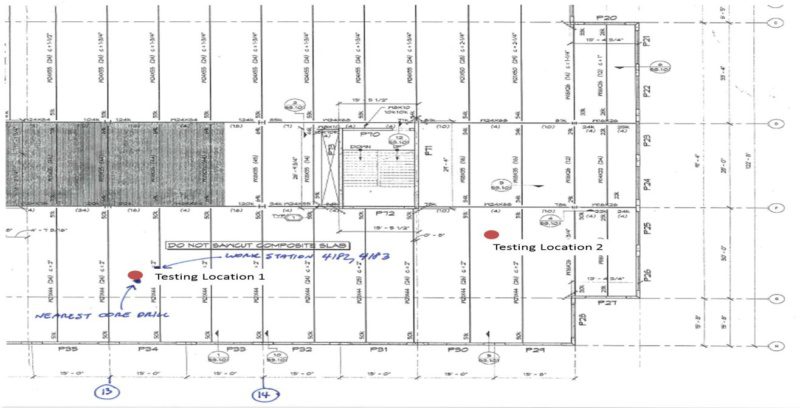

Vibrations at a second location were also tested, but found to be lower in magnitude than workstation 4183. As identified in the structural layout (Figure 3), workstation 4183 was mid-span between the beams and joists crossing the floor, likely contributing to the greater vibration magnitude.

They were placed in a layout running horizontally across the floor, perpendicular to the W21x44 beams that were spaced 10’ apart.

According to the standard, the vibrations were described as Class 3, corresponding to distinctly Perceptible but not strongly perceptible.

Instrumentation

Crystal Instruments Spider 20 Data Acquisition Unit, Serial #: 5462944

PCB Piezotronics Single-Axis Accelerometer, Part #: 393B04, Serial #: 36913

PCB Piezotronics Single-Axis Accelerometer, Part #: 393B04, Serial #: 36795

PCB Piezotronics Single-Axis Accelerometer, Part #: 393B04, Serial #: 36783

PCB Piezotronics Single-Axis Accelerometer, Part #: 393B04, Serial #: 30743

Source of Vibrations

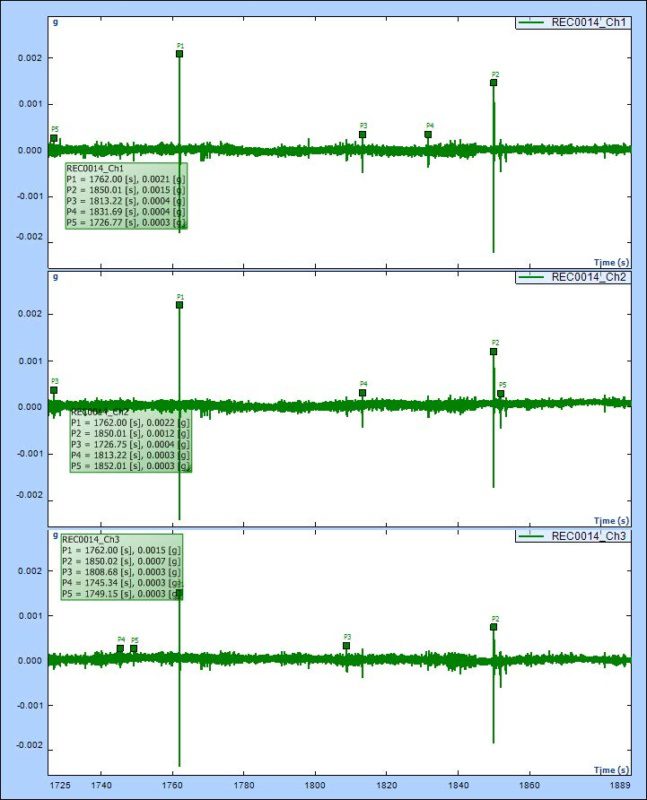

Figure 1: Vibrations due to Walking

After review of the data, there is no pattern to indicate that the vibrations are due to mechanical equipment. This would usually be indicated by periodic changes that were of the same length and magnitude. A brief demonstration was performed by bouncing on the balls of the feet and simulating walking down the hallway. Both demonstrably influenced the transducers, indicating that the source of the vibrations is staff movement. As seen in Figure 1 above, each incident of significant floor vibrations corresponded directly to staff or technician movement. All of the five aforementioned events vary in magnitude and duration but represent the individuals nearest the testing equipment departing their desks for various tasks and returning to their desks.

After discussions with the staff, it was further verified that the vibrations were sporadic throughout the day. This is common in floors with intermediate spans (between 10 feet and 30 feet) because the structure has insufficient stiffness or mass to reduce some vibration.

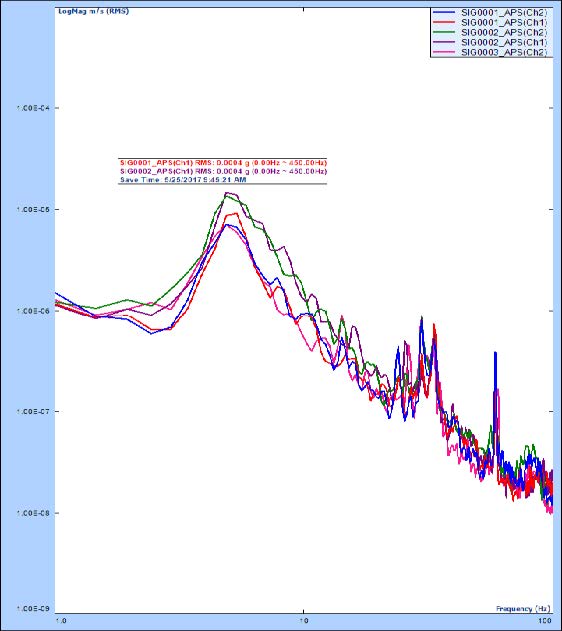

Figure 2 outlines the five RMS (Root-Mean-Square) signals with the greatest magnitude. All are from the first two hours of the day, with measurements taken between 8:44 and 10:44 AM, presumably because that is when the majority of the foot traffic occurred on site.

Figure 2: Vibration Magnitude for Each Test, m/s2 versus Frequency

These vibration levels are well below the acceptable limits in ISO 10137, shown on the right side of Figure 2. This graph shows the magnitude of vibrations in acceleration (m/s2), which peaked at about one level of magnitude below the acceptable limits.

Figure 3: Structural Drawings of 3rd Floor

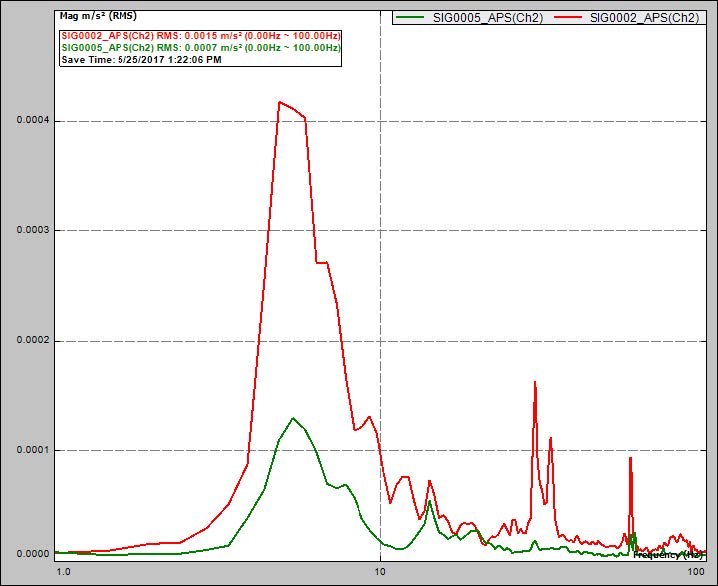

A second set of readings were performed at Testing Location 2, as requested once the team arrived on site. As seen in Figure 4, the magnitude of vibration at the second location was significantly less than the magnitude at Testing Location 1. This is likely due to the proximity to the larger beam in the core of the building. Testing Location 1 is located at mid-span between the larger, stiffer beams.

Figure 4: Magnitude of Vibrations at 2 Different Testing Locations

Path of Vibrations

The testing data indicate the vibrations are propagating through the deck from adjacent footfall. The flooring system consisted of thin Carpet on Concrete (3” Concrete on 3-1/4” Corrugated Deck). No cushion or underlayment was installed under the carpet.

Mitigation Options

Since the office space is fully built-out and in use, construction methods such as stiffening the floor with additional beams are not desirable. However, a number of options are still available, listed below.

- Vibration-Reducing Mats:

- Type: Topical or Underlayment: Since the flooring system is already installed, it would likely be cheaper and faster to install a topical sound reducing mat on top of the existing floor system. A pad such as Pliteq’s GenieMat FIT would be acceptable. This mat will isolate the footfall before it becomes structure-borne in the slab, and will result in a reduced vibration load in the nearby workstations. Other products, such as Commercial Acoustics’ Floor Blokker would be acceptable if installed under the carpeting.

- Location: Hallways or across the entire floor: It is recommended to only install this pad in major walkways, since that is where the majority of the footfall is occurring. While this will not isolate footfall in certain pods, it will address the majority of the footfall while saving significant cost in material and precluding the need to move the existing office equipment.

- Rearranging Office Employees

- As mentioned above, some office employees are more susceptible to vibrations and movement than others. Relocating these staff to more stable portions of the building, especially near the corners and directly next to the central beams will minimize the level of vibrations they feel. Corner locations nearest to two thick beams will be the most stable.

- Future Designs

- By placing beams and joists closer together, the structural engineer may greatly increase the stiffness of the structure so that vibrations due to footfall are not perceptible by employees. Likewise, keeping the same span lengths the same but increasing the depth (and therefore mass) of the floor will result in a heavier floor that will respond less to human-induced movements.

- Simply implementing a dampening underlayment during construction will also reduce the acceleration induced from human movement on the concrete slab.

Conclusion

The vibrations in the office space, while clearly perceptible, were not above the suggested thresholds identified in ISO 10137. While this is a good indicator of the serviceability of the structure, implementing Mitigation Options listed above will reduce the vibrations felt by employees and staff in the office area.