Soundproofing interior walls is a common theme when looking to isolate noisy areas from those requiring more concentration or complete silence. While no wall assembly will ever be completely “soundproof”, you can attain very high levels of sound-blocking, measured in values of STC (Sound Transmission Classification). Many condo associations and building codes require a minimum STC of 50 between adjacent units, or between a living space and public area. While this will allow the developer to meet the bare minimum, this will often-times result in unhappy tenants if the units are near a busy road or other noise source.

Below, find our approach when assessing a wall, and determining the extent and method by which we soundproof it.

Steps to Soundproofing Interior Walls

First, investigate the following elements of the wall.

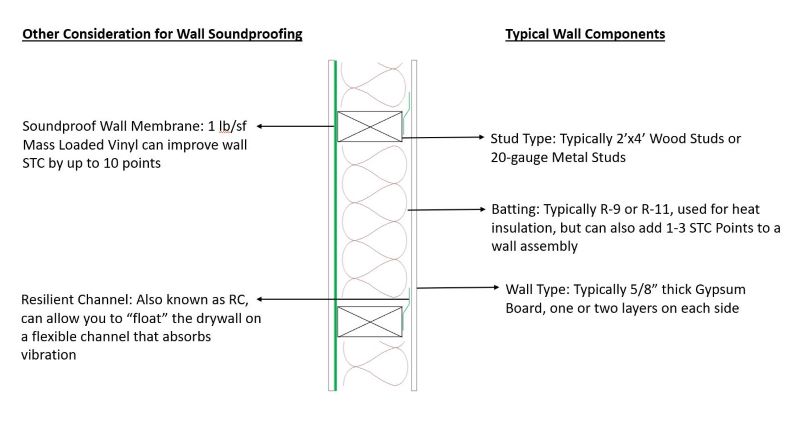

- Studs: these are often wooden 2x4s or steel or aluminum channels that are easy to drill into, but offer enough support for the drywall to hang off of. Determine the type of studs you have, the size, and the spacing – 12 inches on center (which means center-to-center) is common (written as 12” o.c.). You will also find stud spacing at 18” or 24” o.c. for older homes. Greater stud spacing makes the wall less rigid, which means is transmits less structure-borne noise, but may transmit more air-borne noise. Similarly, metal channels are more flexible in the wall, and will reduce noise transfer.

- Batting: a standard batting in walls is R-9 or R-11, all the way to R-60 or higher. The R value only reflects the thermal insulation of the batting, rather than the sound insulation, but there is some correlation between the two. Determine the thickness, width, and type of wall insulation batting being used. Above all, having batting is critical to increase the decibel blocking of the wall. If drywall is already attached, you can still drill a hole and use blown-in insulation.

- Wall Type: the most important element of a wall’s sound-blocking capability are the two (or more) layers of the wall, one on each side of the studs. Determine what type of material these wall layers are composed of, their thickness, and how they are attached to the studs. Most commonly you will see 5/8” thick gypsum board screwed directly into the studs.

- Other Considerations: do you have any soundproofing elements already incorporated in your wall? These would include a Wall Blokker-type material or mass loaded vinyl that increases the weight of the wall. You may also have isolating rails or spacers, or occasionally resilient clips (metal clips that allow the drywall to hang off of the studs by an inch or so). Also, be sure to investigate sound leaks, especially holes around ducting, electrical installations, or other small perforations that allow large amounts of sound to leak through the wall.

See our Soundproofing Membranes to Improve the STC of your Interior Walls

Next, determine “how soundproofed” you need the wall to be. This is done by determining the target STC – Sound Transmission Class. Within an office area, you may find that an STC 35-40 wall is sufficient to diminish noise between adjacent offices, while a home wall may need to be 55-60 to block noise coming off a busy roadway. Classified discussions and home theaters will often require STCs of 65 or higher. Whether you’re trying to muffle conversation or achieve complete privacy, there are a number of options to meet your STC requirements. Once you’ve identified the level of sound-blocking you need, you can begin treating the wall in question.

Finally, determine how to soundproof the wall. Soundproofing a wall is all about 2 variables: how much mass can you add to the wall, and how well can you float the wall from all adjoining surfaces (perpendicular walls, floor, ceiling, adjacent wall layers, etc.).

Adding Mass to Soundproof a Wall

Soundproofing ultimately boils down to the Mass Law – the sound traveling through a medium is inversely proportional to the mass of the medium. Therefore, focus on adding mass to the wall in order to reduce the noise passing through it.

- Increase the size and amount of drywall

And remember, you don’t need to use drywall. If you’re in a garage or other isolated environment, plywood, medium density fiberboard, or other wall coverings may also do the trick just fine. This is a balance between functionality, cost and aesthetics. We suggest at least 5/8” thick drywall, and if possible, adding a second layer on top of that. You will get diminishing returns with each layer of drywall (i.e. a 2nd layer will not block twice as much), but you will still notice the difference.

- Add another element to the drywall

Adding mass to the drywall may also be done with a number of after-market products, designed specifically to go under drywall or directly on top of it. By installing beneath existing drywall, you can focus more on the functionality, and not need to worry much about aesthetics. Examples of this are the Wall Blokker, Wall Blokker Pro, Wall Blokker Lite, and Mass Loaded Vinyl.

There are also special types of acoustic drywall on the market with dense cores that will offer additional weight per square foot. Although these typically run at a high cost per square foot for material and installation, they are relevant in some commercial and industrial applications.

- Add insulation within the drywall

Lastly, it is critical to always maximize the amount of insulation you can fit in the wall cavity. Be sure to fill all remaining voids in the cavity with excess insulation. This insulation should have a high R-value, although any insulation will do much better than none at all. There is some acoustically rated insulation batting on the market, including the QuietFil. While batting is often used for exterior walls, soundproofing interior walls relies on have the cavity filled with some type of absorbing material.

Separating Wall Elements to Soundproof an Interior Wall

While adding mass is extremely effective at blocking airborne sound, you will also need to separate wall elements in order to attenuate structure-borne noise (i.e. vibrations). In the same way that a double-pane window has a vacuum between 2 panes of glass, a wall surface can be separated from an underlying layer so that sound cannot vibrate through the wall.

- Adding a Resilient Channel, such as DecoupLink, can allow you to “float” the drywall on a flexible channel that absorbs vibration.

- Using Staggered Stud design: By staggering the studs along the floor baseplate, neither stud will actually touch both drywall boards simultaneously. This creates a gap that insulates from structure-borne noise. This is a feasible option for new construction, but does reduce the room size by up to 4”.

- Installing soundproof membranes: this product is engineered to decouple between adjacent drywall layers, while also adding mass.

By adding mass to the wall and decoupling layers, you can attenuate both airborne and structure-borne noises. During installation, be sure to watch for unwanted and unanticipated gaps that arise. Installation for complex projects often requires a professional.

Overall, sound-blocking is not a black magic consisting of throwing more money and materials Soundproofing can be so poor nowadays because construction often sacrifices material costs to keep total project costs down. While care is taken to improve aesthetics for “luxury” apartments and condos, they often have far less than ideal acoustics.

Unlike exterior walls that generally have excessive mass due to other criteria (such as wind loads), soundproofing interior walls may require unique soundproofing products. Furthermore, since exterior walls are generally limited by the performance of windows and sliding doors, they should not be over-designed for STCs.

Call today for a free site consultation or acoustic consultation or additional information on any of our products.

Soundproofing a Wall for STC

At the end of the day, high STC performance can be achieved with any type of wall (metal or wood studs, single or double stud) with the inclusion of the proper isolation techniques and materials, including sound membranes. If unique requirements exist for low-frequency performance consider looking beyond simple STC measures, and instead look at frequency-specific soundproofing measures. When unsure, consult an acoustical engineer to define and achieve your wall soundproofing expectations.