There’s a large amount of misinformation regarding the common sound rating criteria used by acoustical consultants and architects; from STC and NRC to IIC and Delta-IIC, many of these various ratings measure significantly different performance metrics of the assemblies in question. Below, we explore the data gathered, analysis performed, and underlying ASTM specifications used to calculate STC, IIC, and delta-IIC ratings.

STC – Sound Transmission Classification

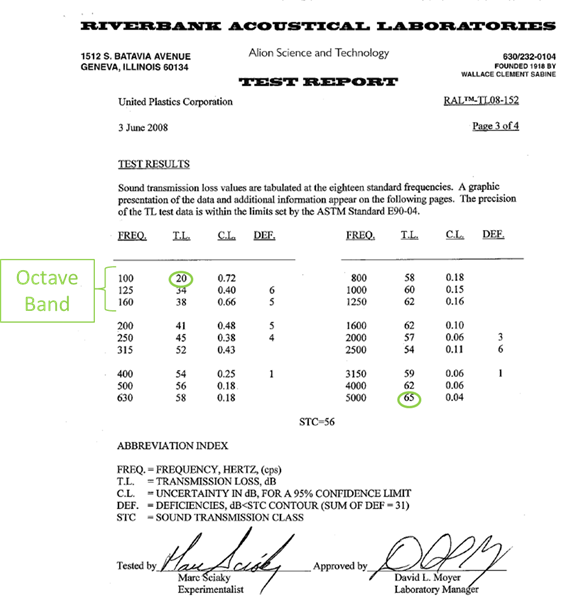

STC stands for sound transmission classification. This rating is given to materials that are tested over a range of frequencies, and are proven to block sound in some capacity. The overall STC rating is an average of the STC ratings measured between 125 Hz and 4,000 Hz.

While STCs are a good one-number approximation for the soundproofing capacity of a wall, they are limited in a few ways:

- STCs are an average of the transmission loss (dB Loss) in a number of frequencies. As such, if you need high attenuation at a specific frequency, the STC alone will not be sufficient to determine if you are achieving it.

- STCs only factor in the transmission loss between 100 Hz and 4000 Hz. For very loud sources, such as movie theater speakers, sound at the 63 Hz and 80 Hz bands may be more important than any frequency band that factors into the STC rating.

The easiest, but less precise way to determine the STC of a partition involves an SPL meter and ambient white noise. First, measure the ambient noise level in the source and receive room, then turn on the white noise and measure that dBA level in the source and receive rooms. Subtract the dBA level in the receive room from the dBA level in the source room, and you’ll know the approximate STC rating of the partition.

To get the exact STC-rating, some more calculations need to be done by the acoustical consultant.

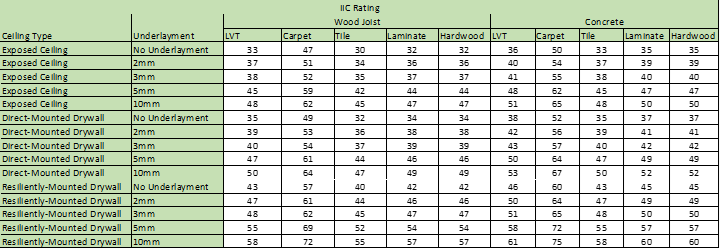

IIC – Impact Insulation Class

IIC stands for Impact Insulation Class. This is the rating given to flooring assemblies and determines how well they mitigate impact noise (footfall mostly). As opposed to STC, IIC rates the flooring assembly as a whole, not just the material on its own.

The different parts of a flooring assembly can include:

- Floor Supports – The rafters or joists running within a floor to support it from caving in or sagging when a load is applied. These are often 2×4, 2×6, or even 2×8 boards of construction lumber, installed so that their greater dimension is vertical to more effectively combat bending moments.

- Substrates – also known as a subfloor, this is the layer installed directly onto the underlying floor supports. It is not the aesthetic layer that you can see when walking into a room, but provides support and additional insulation. The most common substrates are plywood or concrete flooring – with plywood used often in residential or small-commercial applications, and concrete used for large commercial and industrial applications, and grade-level flooring. Other substrates include particle board or OSB (underlayment grade), vinyl composition tile (VCT), cement backer board, or even gypsum and terrazzo (stone & glass composite)

- Flooring Underlayments – the acoustic layer is sometimes included in flooring, especially when there are sound-blocking or absorption requirements. These may range from cork board and carpet cushions to specialized acoustical sound-blocking materials (including our Floor Blokker). While cork board may be effective at reducing some vibration, acoustic floor underlayments provide sound-blocking for structure-borne and airborne noises.

- Top Flooring – the top flooring layer is the aesthetic and functional layer that you see when entering a room. This can range from wood (hardwood, engineered wood, parquet mosaic, or bamboo) to concrete, carpet, or tile.

The test to determine IIC is similar to the STC test. A tapping machine is machine is placed on the floor in the source room (must be second floor or above). The Acoustic Consultant will measure how loud the tapping machine is within the room using an SPL meter. Then, they’ll measure how loud the tapping machine is in the receive room (must be in the room directly below the machine).

Simply put, the IIC rating will be the noise level in the source room, minus the noise level in the receive room. That formula will give you an approximation of the IIC, but the acoustic consultant does have to do some more calculations in order to get the exact rating.

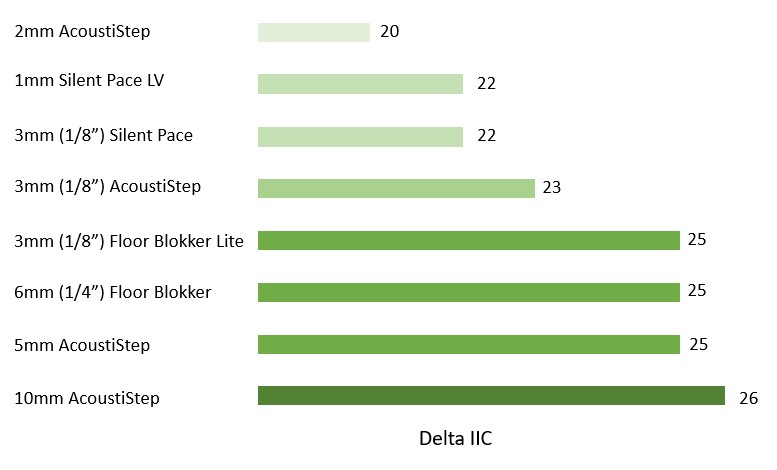

Delta IIC

Delta IIC is a single-number approximation of an underlayment’s effectiveness based on a control hardwood IIC test. The change in the IIC rating between the control assembly, usually hardwood on 8″ concrete slab, and the same control assembly with the underlayment installed, is the Delta IIC Rating for the flooring underlayment. The higher the Delta-IIC, the better the floor underlayment performs to mitigate impact noise.

The major issue with this rating is that it oversimplifies the performance of the underlayment! Many sound mats may say that have a Delta-IIC of 21, but when you see their actual IIC performance on various assemblies, they vary significantly. That is why, when available, IIC tests are highly preferable to Delta-IIC tests.

Some thinner rubber sound mats may achieve a delta-IIC of 21-25, while premium floor underlayments may top out at a delta IIC of 26 or so. Depending on your target IIC (expected building use; multi-family requires a 50+, and most high-end condos should aim for a 60+), any of these sound mats may be acceptable, based on your flooring substrate and assembly.

Delta IIC Rating Chart

Based on the Delta IIC Rating Chart above, the most effective floor underlayments are made from crumbled rubber and greater than 3mm in thickness. Always consider finish floor type and target IIC when selecting the right floor underlayment. For example, it is not acceptable to use an underlayment with significant “give” with ceramic tile finish floor or an LVT less than 5mm thick, otherwise the flooring will indent or even crack as people walk.