A common question many clients have is how to clean their acoustic panels, or if it’s even possible. Since panels are fabricated with special-made acoustically transparent fabric there may be cleaning limitations. Determining the likelihood of damage or wear on your acoustic wall panels should be a major consideration for your fabric selections.

Acoustic Panel Fabrics – Cleanable & Non-Cleanable

If your acoustic panels are likely to be used in areas where food is consumed or children are present, you should plan on selecting a washable acoustically transparent fabric. Fabrics come with a number of cleaning codes.

Standard Cleanable Fabrics:

- FR701

- Whisper

- Anchorage

Vacuuming or light dusting is recommended. May also be disinfected with hydrogen peroxide or alcohol. Apply cornstarch with a toothbrush or other fine-bristled instrument and then vacuuming it out is a solution we’ve used many times over the years.

Some fabrics may also be cleaned with bleach. This should be considered in areas where significant wear and tear is expected, or where high levels of cleanliness are required.

Bleach Cleanable Fabric:

- Studio 54

Disinfecting Acoustic Panels:

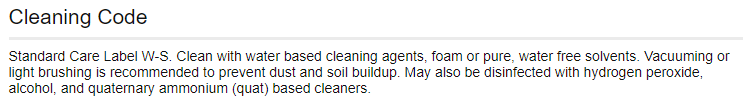

Before disinfecting your acoustic panels, make sure you know which fabric type you use, and follow the proper cleaning instructions. Guilford of Maine fabrics with cleaning code W-S can be disinfected using hydrogen peroxide based cleaners, alcohol-based cleaners, and quat-based cleaners. Fabrics with cleaning code W-S and Bleach Cleanable can be cleaned using bleach-based cleaners, hydrogen peroxide-based cleaners, alcohol-based cleaners and quat-based cleaners.

Guilford of Maine Cleaning & Disinfecting Guide

Never saturate the panel with the cleaner, use a spray bottle to apply the cleaner and a cloth to gently wipe the fabric.

Preventing Stains on Acoustic Wall Panels

While understanding how to clean acoustic panels is important, it’s equally critical to prevent panel staining initially. Panels will ideally be hung above 8′-10′ where they cannot be easily touched (by children or adults). By putting panels out of arms-reach, you can prevent the buildup of oil and dirt from curious hands. Many products are available on the market to provide stain prevention on the fabric itself, the most common might be Scotchgarde. By applying a thin mist, per the manufactures instructions, the fabric may be more easily cleaned in the future. NOTE: this may need to be applied at intermittent intervals for preventive maintenance.

Also, consider selecting colors that less easily show dirt and dust. White panels hung at eye height will show every spec of dirt from the construction and installation process, while dark colored panels hung up in an exposed ceiling will be very difficult to notice any imperfections.

Acoustic wall panels should be installed as one of the final elements prior to occupancy. Protective plastic wrap shall remain on the panels until final punch out. Installation should not occur until all paint has dried for at least 24-48 hours.

Acoustic Panel Color Fastness

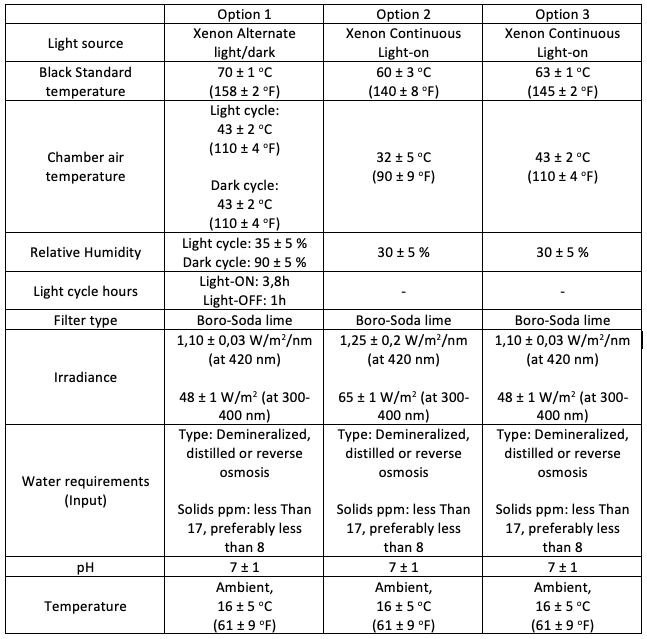

Another concern for designers may be the duration of which panels can be expected to maintain their original color. In the acoustic wall panel industry, we call this color fastness per AATCC 16.3.

Fabric may fade in the presence of UV light, direct exposure to the sun, or close proximity to heating sources, such as lighting fixtures and lamps. Premium acoustical fabrics have color fastness ratings of at least 4.