Armature Works is a completely restored, mixed-use building in the historic Tampa Heights neighborhood along the Hillsborough River. Opening late 2017, the space will feature eateries, a public market, event spaces, and co-working space.

An event space on the second level of the building that was already open for use was experiencing noise disturbances coming from the bottom floor. Sound from the kitchen and other facilities below was causing noise complaints during events, decreasing guest satisfaction.

Armature Works came to Commercial Acoustics for a solution to this noise problem. We chose to use Floor Blokker, an effective method for blocking noise coming through the floor. This product reduces airborne and impact noise by 75%, ideal for reducing sound coming from downstairs. This will also prevent noise and footfall from events in this space from disturbing the bottom floor.

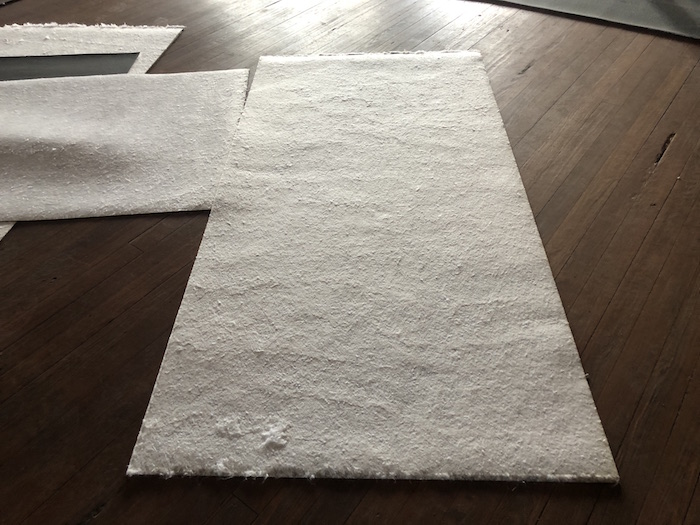

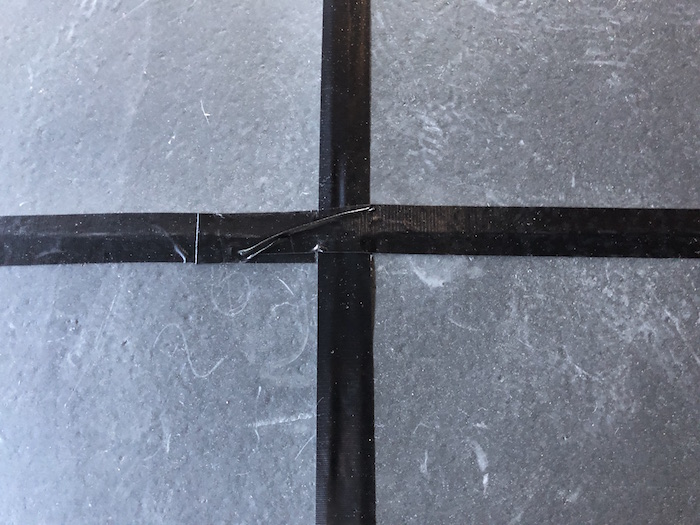

Installation of Soundproofing Membrane In Event Space

We installed the product by first laying down a level of adhesive underneath the Floor Blokker, then another layer of adhesive, followed by a layer of EVA. Hard wood flooring was then laid down on top. These layers effectively trap and stop noise from traveling between floors.

If your business is facing similar noise disturbances as Armature Works, read here for floor soundproofing tips.

See our installation process through the photos below.

Remember that, when soundproofing existing hardwood floors, you can apply STC-rated soundproofing membranes to the existing floor, then float a new floor on the completed assembly. This approach worked to great affect at Armature Works, allowing the client an event space with sufficient sound attenuation, while still maintaining a rustic, original aesthetic on the floor above.