One of the most ideal uses for soundproofing membranes is when low-frequency reduction is critical to the performance of a system. This is especially true with entertainment and industrial venues, where low-frequency noise is generated from equipment and amplified speakers. A recent case study with a luxury cinema in Dallas, Texas serves as a prime […]

Monthly Archives: February 2017

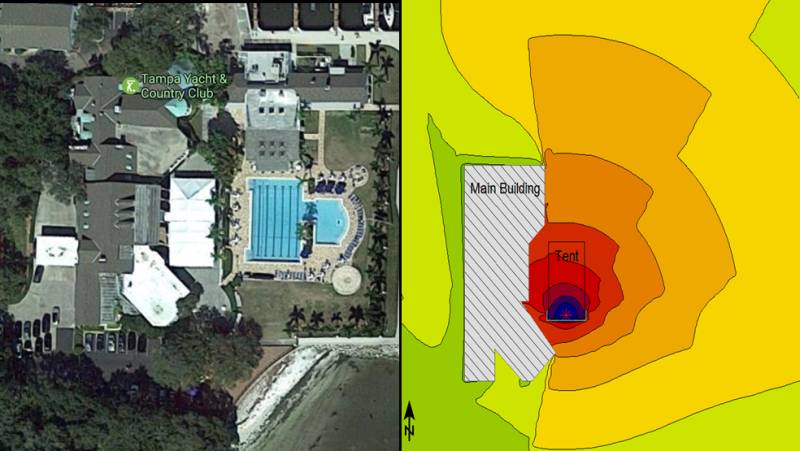

The Tampa Yacht and Country Club was struggling with an exterior acoustics issue. While it is a beautiful venue with a history of hosting elegant events, this also led to large wedding parties that sometimes were louder than local neighbors appreciated. And while many clubhouses deal with echo and reverb problems, this was a unique […]