Sound Issues in the Old Hotel Initially opened in the 1920s, the historic Fenway Hotel is due to be reopened later this year as a boutique hotel. While the transformation included cosmetic and functional upgrades, there was one portion of the hotel renovation that called for soundproofing expertise – the noise transfer between rooms. Construction […]

Monthly Archives: January 2017

When designing or building a new movie theater, it is critical to consider the movie-watching experience, from seating locations to auditorium reverberation and attenuation between adjacent theaters. Soundproofing the movie theater is one of the key considerations. Challenges of Soundproofing Movie Theaters Whether you have unique sound requirements or standard THX constraints, the wall thickness, […]

It’s a common occurrence: you see a 1-page data sheet claiming light-weight and inexpensive materials getting IIC – Impact Insulation Class – ratings of 70 or higher. These data sheets are littered with incomplete information and undefined assemblies. When you request the test data, it’s either difficult to attain, or when received, completely irrelevant. So, […]

While there is significant literature and testing available for interior wall partitions, many planning and architect professionals run into issues of exterior noise control. In Europe, where often-times it is required to perform a Sound Study prior to new development, the US and many other countries are in a build and react mode. This sometimes […]

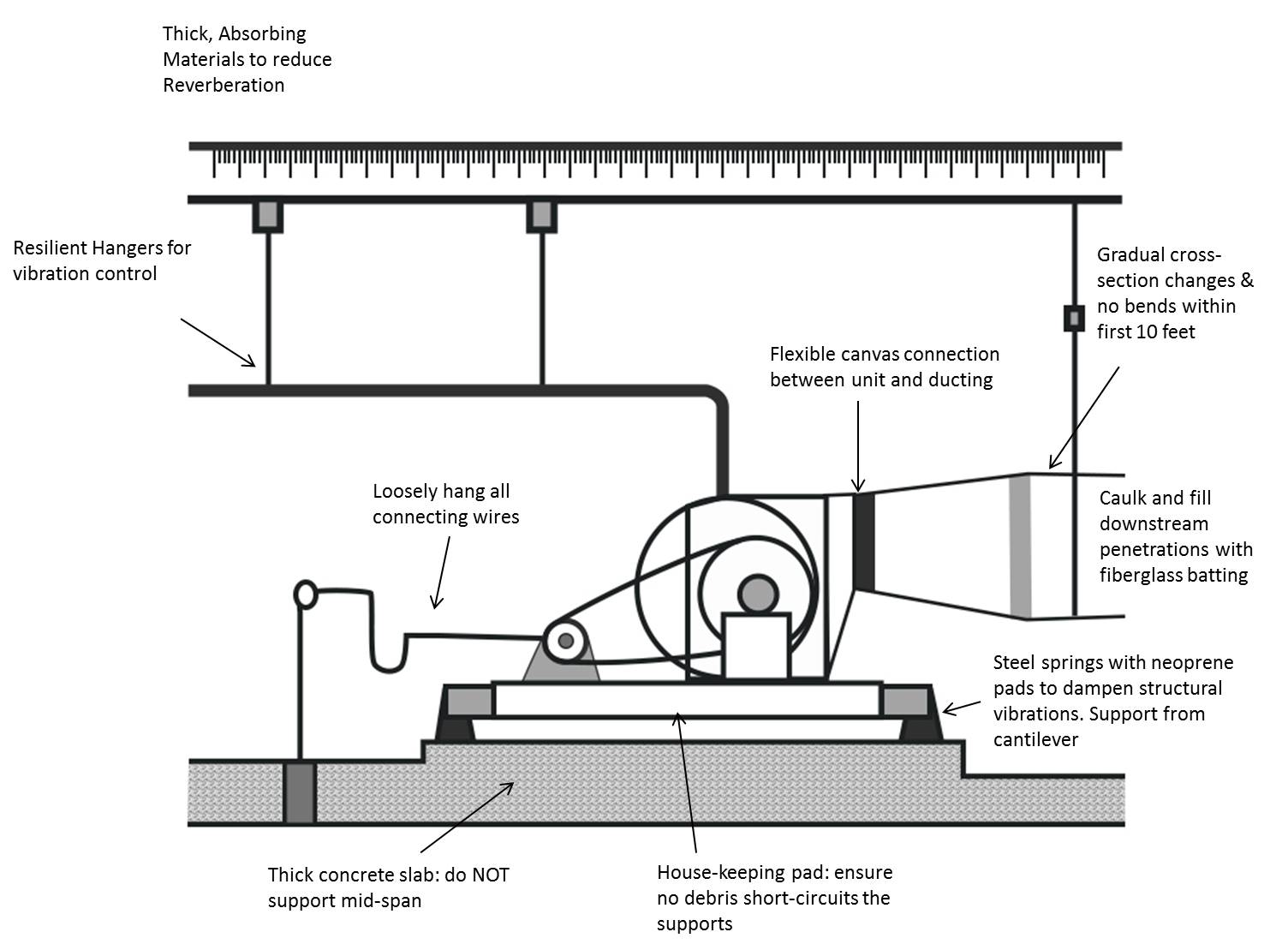

Find Basic Tips for Reducing Mechanical Noise There are a number of mechanical systems in nearly every building that can cause annoying hums, drums and vibrations. Unlike traditional soundproofing and absorption techniques, these are dependent on a number of other characteristics innate in the machine’s operation – including size, frequency, and mounting conditions. Treating a […]

After another record-breaking year, Commercial Acoustics has been recognized as one of GrowFL’s Florida’s Companies to Watch in 2017. Florida Soundproofing Firm Expands Across Southeast US Commercial Acoustics focuses on soundproofing and acoustical solutions, and has a strong market in Florida, Georgia, and Alabama. They have a number of innovative soundproofing membranes used in hotels, […]

Commercial Acoustics was contracted to perform acoustic consulting services for a multi-family property in upstate New York where residents were complaining of excessive noise, particularly from adjacent stairways and from footfall above. After initial review and discussion with the client, Commercial Acoustics traveled to the site and performed a number of acoustical tests for structure-borne (AIIC) […]

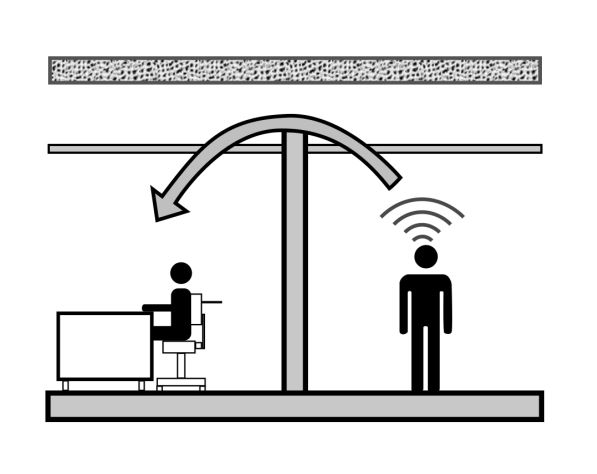

One of the most common complaints we see in office and educational settings is flanking noise through open plenums between adjacent spaces. This is often problematic when walls between offices don’t go to deck allowing sound to pass directly through the Acoustic Ceiling Tile and allowing clearly audible conversations between neighbors. (Note: ACT are not […]

While many restaurateurs struggle with acoustic issues, some are more critical than others. Take for instance, Tampa’s downtown Channelside restaurant Cena. A high-end Italian Cafe focused on upscale Mediterranean cuisine, the restaurant was a perfect storm of underlying acoustical concerns. The walls were painted gypsum with a significant square footage of windows. Meanwhile the tall […]