When you see “Wall Covering”, or WC, in an Architectural Drawing Set, it can be interpreted or defined as a few different things. We often see Wall Coverings, Acoustical Wall Coverings and Vinyl Wall Coverings, and even Stretched Fabric Wall but what makes each one of these products unique? How is a Stretched Fabric Wall […]

Category Archives: Soundproofing Tips

Many architects understand the value that stretched fabric acoustical systems bring to their designs. As both an aesthetic element, with high function acoustical absorption values, the stretched fabric wall helps to achieve two primary objectives on many architectural programs, from class A office to auditorium and assembly spaces. Unlike traditional prefabricated acoustical wall panels, which […]

What are NR, NIC & STC? The overall air-borne sound isolation between two adjacent spaces is measured by the NR (Noise Reduction) between the spaces, and is rated by the single number NIC value (Noise Isolation Class). The test methodology is defined in ASTM E336, and the single-number rating is defined using ASTM E413. NIC […]

When are Acoustical Diffusers Required for Sound Treatment? Acoustical Diffusers are typically used in band rooms, auditoriums, or any venue where music instruments will be played. They should be used along with acoustic wall panels to help balance the absorption and reflection of high and low frequencies to produce a higher sound quality. Using acoustical […]

Common Mistakes with Resilient Channel Use of Resilient Channel on walls with mounted objects This mistake leads to an immediate STC reduction of 5-6 points or more. Mounted objects, such as TVs, cabinets, book cases, shelves, or other products that are not mounted with drywall anchors, create a structural bridge which greatly reduces the effectiveness […]

When specifying and designing a Sound Masking System, there are a number of considerations, including the type of system to be used, spacing of speakers, and desired masking levels. Types of Sound Masking Direct vs. Diffuse Fields: Conceptually, a direct field is one where there is a line-of-sight path between the source and receiver, while […]

Speech privacy is a common issue in law offices, where confidential or private information is regularly discussed. Unlike many commercial office spaces where lack of speech privacy is only a nuisance, there may be legitimate legal concerns in law offices specifically. Commonplace in healthcare and financial industries, sound masking provides a level of background white […]

A common question many clients have is how to clean their acoustic panels, or if it’s even possible. Since panels are fabricated with special-made acoustically transparent fabric there may be cleaning limitations. Determining the likelihood of damage or wear on your acoustic wall panels should be a major consideration for your fabric selections. Acoustic Panel […]

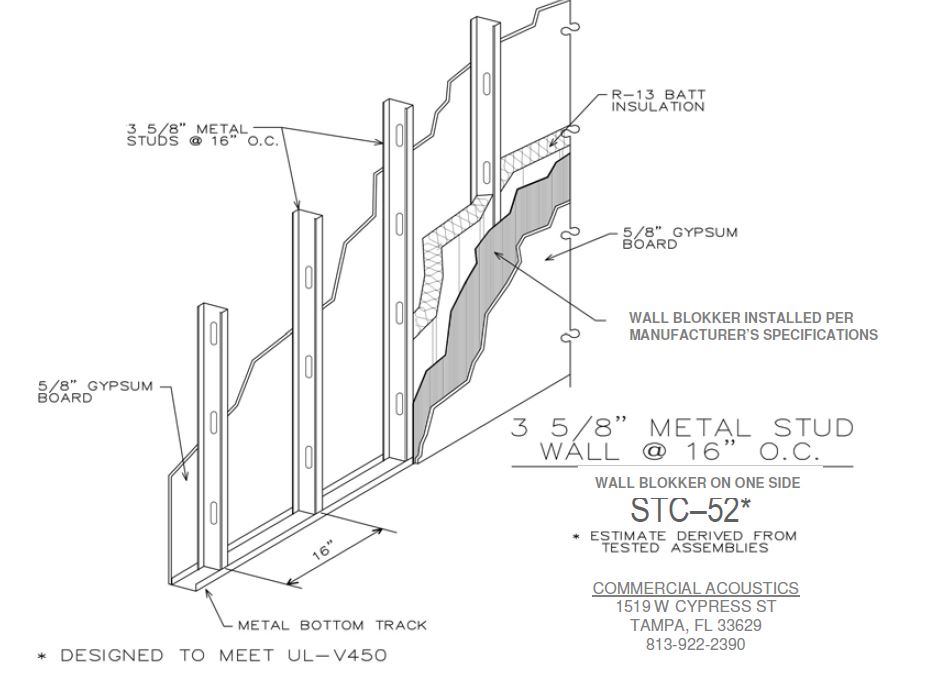

Accurate Acoustic Details are a critical element to any project’s ultimate success. While great care is generally taken to specify STC-rated wall assemblies and IIC-rated flooring assemblies, the field performance is often highly dependent on details including boundary conditions, edge interfaces, and treatment of wall and floor penetrations. Architectural Acoustic Details are equally critical to […]

There’s a large amount of misinformation regarding the common sound rating criteria used by acoustical consultants and architects; from STC and NRC to IIC and Delta-IIC, many of these various ratings measure significantly different performance metrics of the assemblies in question. Below, we explore the data gathered, analysis performed, and underlying ASTM specifications used to […]